Stretchy, flexible gas sensors can detect oxygen or carbon dioxide levels in the breath or perspiration to detect health disorders or concerns when utilized as wearable medical equipment.

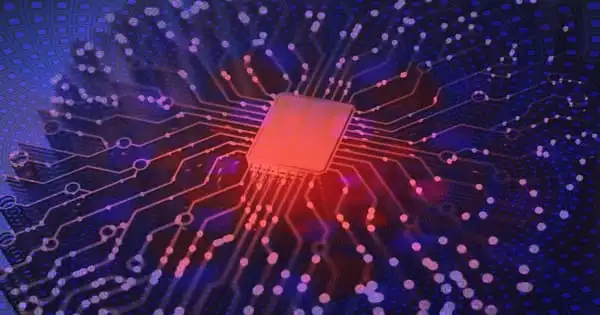

By detecting gases, biomolecules, and chemicals, they are also helpful for keeping an eye on the quality of the air in enclosed or open spaces. The gadgets are made with nanoparticles, but manufacturing them can be difficult.

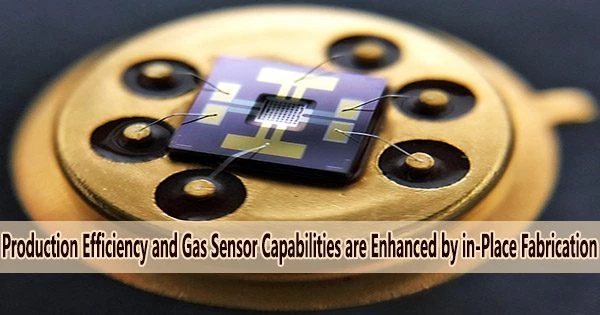

Researchers from Penn State recently improved their method for drop casting, or the process of dropping materials one by one onto a substrate using a pipette, to create gas sensors by adopting an in situ laser-assisted manufacturing methodology. They published their results in the Chemical Engineering Journal.

“With drop casting, you have to synthesize each part of the sensor separately and then integrate them, which is logistically challenging, takes a long time and is expensive,” said corresponding author Huanyu “Larry” Cheng, James L. Henderson, Jr. Memorial Associate Professor of Engineering Science and Mechanics in the Penn State College of Engineering. “The in situ method allows the materials to be directly synthesized in one place, and the laser speeds up the process.”

During the procedure, a porous graphene foam substrate is covered with nanoparticles that have been laser-inscribed. Whether applied to skin or an object, the sensor can be stretched and bent thanks to the base material.

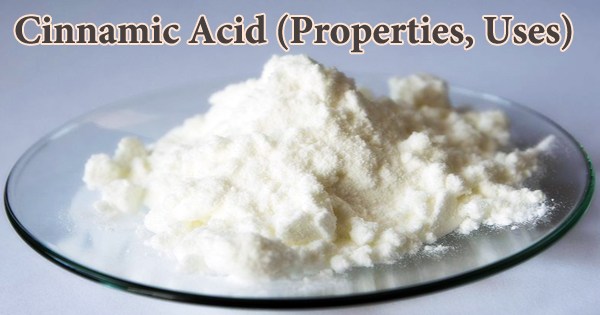

A particular nanomaterial allows us to sense different biomarkers or gases, so it’s very important for us to get access to different materials. For example, one nanomaterial usually can only detect one target gas molecule. With multiple choices available, you can potentially detect more molecules, improving the sensing capabilities.

Huanyu “Larry” Cheng

The method, in Cheng’s opinion, provides options to combine various precursors or nanomaterials in various proportions. Graphene oxide and molybdenum disulfide were previously utilized by researchers to make the sensors.

Researchers examined four additional kinds of materials using the novel technique, including metal oxides, transition metal dichalcogenides, metal oxides with noble metal doping, and composite metal oxides.

“A particular nanomaterial allows us to sense different biomarkers or gases, so it’s very important for us to get access to different materials,” Cheng said. “For example, one nanomaterial usually can only detect one target gas molecule. With multiple choices available, you can potentially detect more molecules, improving the sensing capabilities.”

Researchers using various nanomaterials made the array of several little sensors that were positioned next to one another. “The capabilities of the array can be compared to a human nose,” Cheng said.

“The nose evolved to detect millions of smells using millions of cells,” Cheng said. “In the same way, each of the sensors is able to detect a different chemical or particle.”

Researchers reduced the complexity of producing the device by doing away with the necessity for a separate heat source with the new sensor design. As opposed to the previous design, which used nanoparticles to fill the spaces between the electrodes, the new one merges the gas-sensitive nanomaterials onto a single line of porous graphene foam. One line of porous graphene foam experiences resistance, which generates Joule heat for self-heating.

The end product is an advanced sensor with many uses, such as monitoring and warning the user of a sudden increase in gases, as may occur on an industrial site, or a buildup of gases over time, as might occur in the event of pollution.

By programming nanomaterial composites to target certain gases or to recognize numerous gas species in complicated mixes, researchers hope to enhance the sensor’s capabilities in the future.