Biohydrogen is a form of hydrogen gas (H2) produced biologically, often by microorganisms such as bacteria and algae. H2 is the product of biological processes. This method is gaining popularity since H2 is a clean fuel that can be easily created from certain types of biomass, including biological waste. It is seen as a promising renewable energy source since it can be produced using organic matter or biomass as a feedstock, and it has the potential to be a clean and sustainable alternative to fossil fuels. Additionally, some photosynthetic microbes can create H2 directly from water splitting utilizing light as their energy source.

Aside from the promising possibilities of biological hydrogen production, this technique faces numerous hurdles. The first obstacles are those inherent to H2, such as storing and transporting an explosive noncondensible gas. Furthermore, O2 poisons hydrogen-producing organisms, resulting in low H2 outputs.

The main process for biohydrogen production is called “biological hydrogen production” or “biological hydrogen fermentation.” This process typically involves the following steps:

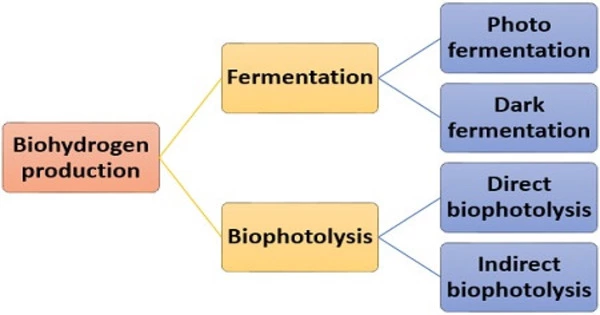

- Fermentation: Microorganisms, such as hydrogen-producing bacteria, are used in a sequence of biochemical reactions to break down organic substances such as sugars, cellulose, or other biomass materials. As a metabolic byproduct, hydrogen gas is created during this process.

- Fermentation Types: Dark fermentation and photofermentation are two types of fermentation processes for biohydrogen generation. In the absence of light, dark fermentation occurs, whereas photofermentation relies on photosynthetic bacteria such as algae to create hydrogen in the presence of light.

- Feedstocks: It can be made from a variety of organic sources, including agricultural waste, wastewater, sewage sludge, and energy crops such as switchgrass or algae. The feedstock used can have a considerable impact on the efficiency and sustainability of biohydrogen production.

- Bioreactors: Biohydrogen production is frequently carried out in specialized bioreactors where environmental parameters such as temperature, pH, and nutrient supply are carefully monitored in order to optimize the growth and activity of hydrogen-producing bacteria.

- Purification: Following the creation of biohydrogen, the gas must be filtered to remove contaminants such as carbon dioxide and other gases. This is normally accomplished through the use of various separation and purification processes.

Biohydrogen production has a number of advantages, including the ability to minimize greenhouse gas emissions because the process can be carbon-neutral provided sustainable feedstocks are used. It does, however, confront obstacles such as low yields, competition from other metabolic pathways in microbes, and the need for enhanced bioprocess engineering to make it commercially feasible.