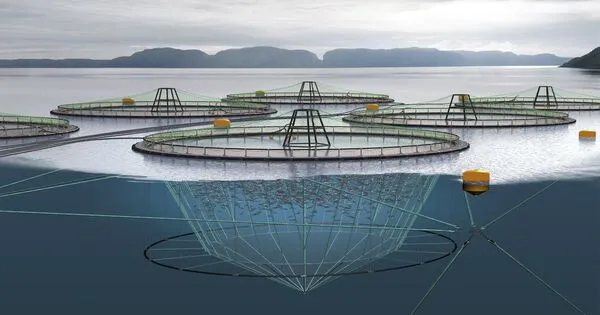

Copper alloys are significant netting materials in aquaculture (the farming of aquatic creatures, especially fish farming). Because of their beneficial features, including as corrosion resistance, antibacterial capabilities, and durability, they are extensively employed in aquaculture for a variety of purposes. Other materials for netting in aquaculture fish cages around the world include nylon, polyester, polypropylene, polyethylene, plastic-coated welded wire, rubber, proprietary twine products (Spectra, Dyneema), and galvanized steel. All of these materials were chosen for a variety of reasons, including design feasibility, material strength, cost, and corrosion resistance.

Aquaculture is the production of aquatic organisms such as fish, shellfish, and aquatic plants, and copper alloys are used in a variety of applications within this industry. Copper alloys differ from other materials used in fish farming in that they are antimicrobial, meaning they kill bacteria, viruses, fungi, algae, and other germs. (For more information on the antibacterial characteristics of copper and its alloys, see antibacterial properties of copper and Antimicrobial copper alloy contact surfaces.

Here are some ways copper alloys are utilized in aquaculture:

- Netting and Cages: Copper alloys, particularly those incorporating nickel and aluminum, are frequently used to make aquaculture nets and cages. These metals were chosen because they are resistant to corrosion in the aquatic environment, allowing these important infrastructure components to last longer.

- Antifouling: To reduce fouling, copper-based paints and coatings are used on aquaculture equipment, boats, and structures. Because copper is harmful to many marine creatures, including algae and barnacles, it aids in the cleaning of surfaces. This is critical for preserving water quality and lowering maintenance expenses.

- Water Treatment: Copper ions can be used in water treatment processes to control algae and other undesirable microorganisms in aquaculture systems. Copper ions effectively kill or inhibit the growth of these organisms, helping to maintain water quality.

- Aquariums and Tanks: Copper-based alloys are used in the construction of aquariums and tanks for both commercial and research purposes. They are chosen for their durability and resistance to corrosion in a saltwater environment.

- Feeding Equipment: Some feeding equipment used in aquaculture may be made from copper alloys. These alloys are chosen for their resistance to corrosion and ease of cleaning, ensuring that the equipment remains hygienic.

Copper alloys are also employed to make aquaculture medications and treatments. Copper sulfate, for example, is occasionally used to cure certain fish infections. However, it should be used with caution because too much copper can be hazardous to fish and other aquatic species.

Copper alloys’ antimicrobial/algaecidal properties prevent biofouling in the marine environment, which is defined as the undesirable accumulation, adhesion, and growth of microorganisms, plants, algae, tube worms, barnacles, mollusks, and other organisms on man-made marine structures. Copper alloy aquaculture pens eliminate the need for costly net replacements that are required with other materials by limiting microbial growth. The resistance of organism growth on copper alloy nets also provides a cleaner and healthier environment for farmed fish to grow and thrive.