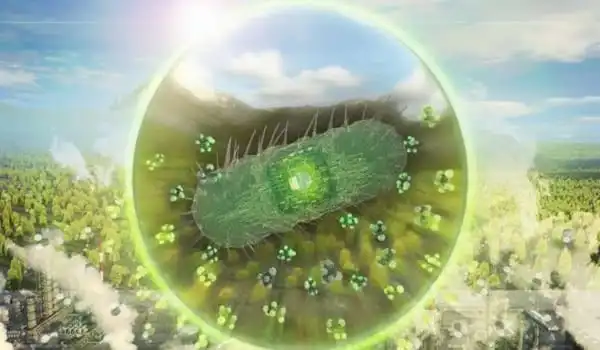

A type of bacteria was developed by researchers to break down carbon dioxide (CO2) and transform it into commonly used, pricey industrial compounds. The carbon-negative technique removes CO2 from the atmosphere while avoiding the use of fossil fuels to produce these compounds.

Bacteria are recognized for breaking down lactose, which is used to make yogurt, and sugar, which is used to make beer. Researchers from Northwestern University and LanzaTech have now used microbes to break down waste carbon dioxide (CO2) and produce valuable industrial compounds.

The researchers chose, developed, and optimized a bacteria strain in a new pilot study, and then successfully demonstrated its ability to convert CO2 into acetone and isopropanol (IPA).

This innovative gas fermentation technique not only removes greenhouse gases from the atmosphere, but it also avoids the use of fossil fuels, which are traditionally used to make acetone and IPA. After doing a life-cycle analysis, the team discovered that if broadly adopted, the carbon-negative platform may reduce greenhouse gas emissions by 160 percent when compared to conventional techniques.

The rising climate crisis, combined with high population expansion, pose some of humanity’s most pressing concerns, all linked to the uncontrolled production and accumulation of CO2 over the whole biosphere. By using our ability to collaborate with biology to produce what is required, where and when it is required, on a sustainable and renewable basis, we can begin to capitalize on the abundant CO2 to alter the bioeconomy.

Michael Jewett

The findings will appear in the journal Nature Biotechnology.

“The rising climate crisis, combined with high population expansion, pose some of humanity’s most pressing concerns, all linked to the uncontrolled production and accumulation of CO2 over the whole biosphere,” said Michael Jewett, co-senior author of the study at Northwestern. “By using our ability to collaborate with biology to produce what is required, where and when it is required, on a sustainable and renewable basis, we can begin to capitalize on the abundant CO2 to alter the bioeconomy.”

Jewett is the Walter P. Murphy Professor of Chemical and Biological Engineering at Northwestern’s McCormick School of Engineering and director of the Center for Synthetic Biology. He co-led the study with Michael Koepke and Ching Leang, both researchers at LanzaTech.

Acetone and IPA are common industrial bulk and platform chemicals, with a combined global market worth more than $10 billion. IPA, which is widely used as a disinfectant and antiseptic, is the foundation for one of two World Health Organization-recommended sanitizer formulae that are highly effective in eradicating the SARS-CoV-2 virus. Acetone is also a solvent for various plastics and synthetic fibers, as well as a thinning agent for polyester resin, cleaning equipment, and nail polish remover.

While these chemicals are extremely beneficial, they are produced using fossil fuels, resulting in climate-warming CO2 emissions.

The researchers created a new gas fermentation process to produce these compounds in a more sustainable manner. They began with Clostridium autoethanogenum, a LanzaTech-engineered anaerobic bacteria. The researchers then utilized synthetic biology methods to reprogram the bacteria to ferment CO2 in order to produce acetone and IPA.

“These improvements, pioneered by cell-free methodologies that drove both strain engineering and route enzyme optimization, shortened time to production by more than a year,” Jewett explained.

The Northwestern and LanzaTech teams believe the new strains and fermentation process will be applicable on a larger scale. The method could also be used to develop more efficient ways for producing other valuable compounds.

“This discovery is a significant step toward avoiding a climate disaster,” said Jennifer Holmgren, CEO of LanzaTech. “Today, the vast majority of our commodity chemicals are sourced solely from new fossil fuels such as oil, natural gas, or coal. Acetone and IPA are two examples, each with a $10 billion global market. The established acetone and IPA pathways will speed up the development of various new products by closing the carbon cycle for usage in a variety of sectors.”

The new fermentation process has two advantages: it eliminates greenhouse emissions from the atmosphere and it avoids the use of fossil fuels, which are traditionally used to produce acetone and IPA. After doing a life-cycle analysis, the researchers discovered that if carbon-negative platforms are widely adopted, they can reduce greenhouse gas emissions by 160 percent when compared to current techniques.

Meanwhile, the escalating climate problem, paired with population expansion, poses some pressing challenges for humanity, all of which are linked to uncontrolled CO2 emissions and accumulation across the entire biosphere.