Torrefaction is a thermal process to convert biomass into a coal-like material, which has better fuel characteristics than the original biomass. Torrefaction of biomass, e.g., wood or grain, is a mild form of pyrolysis at temperatures typically between 200 and 320 °C. This stage is key to the whole process as the bulk of the depolymerization of the biomass takes place in this stage. Torrefied biomass is more brittle, making grinding easier and less energy-intensive. Torrefaction changes biomass properties to provide a better fuel quality for combustion and gasification applications. Compared to fresh biomass, storage of the torrefied material can be substantially simplified since biological degradation and water uptake is minimized. Torrefaction produces a relatively dry product, which reduces or eliminates its potential for organic decomposition.

Biomass can be an important energy source. Torrefaction involves the heating of biomass in the absence of oxygen to a temperature of typically 200 to 400°C. However, there exists a large diversity of potential biomass sources, each with its own unique characteristics. The history of torrefaction dates to the beginning of the 19th century, and gasifiers were used on a large scale during the Second World War.

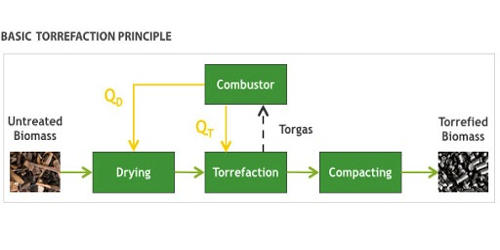

Fig: Torrefaction — Superior Pretreating Method for Biomass Fuel

Process

Torrefaction is a thermochemical treatment of biomass at 200 to 320 °C (392 to 608ºF). It is carried out under atmospheric pressure and in the absence of oxygen, i.e. with no air. During the torrefaction process, the water contained in the biomass as well as superfluous volatiles are released, and the biopolymers (cellulose, hemicellulose, and lignin) partly decompose, giving off various types of volatiles. The structure of the biomass changes in such a way, that the material becomes brittle and more hydrophobic. The final product is the remaining solid, dry, blackened material that is referred to as torrefied biomass or bio-coal. During the torrefaction process, combustible gas is released, which is utilized to provide heat to the process.

Torrefaction is an upgrading process of biomass for other energy generation processes like direct combustion on an industrial scale. During the process, the biomass typically loses 20% of its mass (bone dry basis) and 10% of its heating value, with no appreciable change in volume. This energy (the volatiles) can be used as a heating fuel for the torrefaction process. After the biomass is torrefied it can be densified, usually into briquettes or pellets using conventional densification equipment, to increase it’s mass and energy density and to improve its hydrophobic properties. It is the thermal degradation of organic biomass in an inert or nitrogen atmosphere, one-atmosphere pressure, and temperature in the range of 200–300°C, for several hours depending on the biomass. The final product may repel water and thus can be stored in moist air or rain without appreciable change in moisture content or heating value, unlike the original biomass.