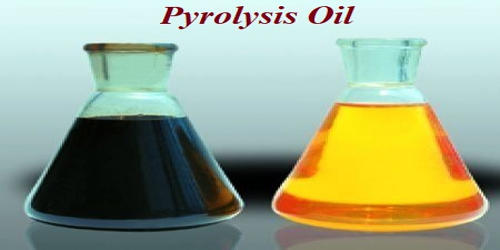

Pyrolysis oil, also known as bio-crude or bio-oil, is a synthetic fuel under investigation as a substitute for petroleum. It is a liquid substance obtained in the pyrolysis process and subsequent cooling. It is obtained by heating dried biomass without oxygen in a reactor at a temperature of about 500 °C with subsequent cooling. It is a complex blend of molecules usually consisting of more than 200 different compounds resulting from the depolymerization of products treated in pyrolysis. This oil could be successfully combusted provided the air inlet temperature was increased to 100–120 °C at an engine compression ratio of 17.6. This temperature can be reduced by approximately 40 °C when the compression ratio is increased to 22.4.

Pyrolysis oil is a kind of tar and normally contains levels of oxygen too high to be considered a pure hydrocarbon. Generally, this oil fuelling led to an increase in CO emission and a decrease in NOx emission. This high oxygen content results in non-volatility, corrosiveness, immiscibility with fossil fuels, thermal instability, and a tendency to polymerize when exposed to air. As such, it is distinctly different from petroleum products. Apparently, peak temperatures in the cylinder are lower upon fuelling pyrolysis oil. Removing oxygen from bio-oil or nitrogen from algal bio-oil is known as upgrading.

Pyrolysis oil remains an interesting source of biochemicals and renewable compounds that meet significant market interest. A ‘duration’ experiment of 40 h was carried out while fuelling pyrolysis oil, without any notable effect on flue gas emissions and fuel consumption. Although often high LHV (12 – 22 MJ/kg), oil from the waste pyrolysis process requires further treatment to ensure it’s stability and compatibility with existing petroleum-based fuels. This is considered as a very promising result, but further long-term testing will be required.

Directions of pyrolysis oil utilization: This oil can be used in several applications to produce heat, electricity, and cooling.

- source of bio-molecules

- fuel for further refining

- food aromas (liquid smoke)

- pesticides and plant enhancers (wood vinegar)

Typical industrial applications of this oil as a fuel: Boilers, Furnaces, Hot Water Generators, Hot Air Generators, Thermic Fluid Heater, Electric Generators (mixed with 50% diesel), Diesel Pumps (mixed with 50% diesel), etc.