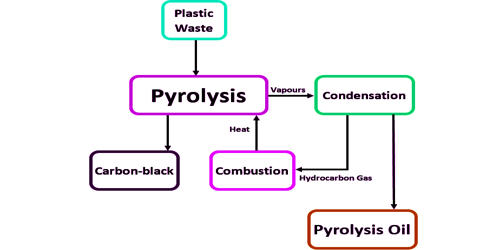

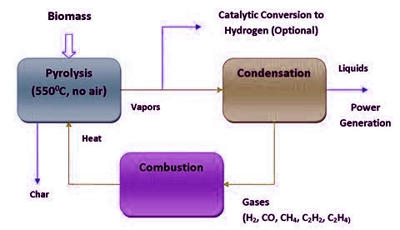

Pyrolysis is one of several means of production of liquid fuel from biomass. It is the decomposition brought about by high temperatures. It is one of several means of production of liquid fuel from biomass. It is the thermal decomposition of materials at elevated temperatures in an inert atmosphere. It is a thermochemical treatment, which can be applied to any organic (carbon-based) product. It involves a change in chemical composition. It can be done on pure products as well as mixtures. The word is coined from the Greek-derived elements pyro “fire” and lysis “separating”.

Pyrolysis is most commonly used in the treatment of organic materials. It is one of the processes involved in charring wood. But contrary to combustion and gasification processes, which involve entire or partial oxidation of material, pyrolysis bases on heating in the absence of air. In general, the pyrolysis of organic substances produces volatile products and leaves a solid residue enriched in carbon, char. The decomposition takes place thanks to the limited thermal stability of chemical bonds of materials, which allows them to be disintegrated by using the heat. Extreme pyrolysis, which leaves mostly carbon as the residue, is called carbonization. Pyrolysis is considered as the first step in the processes of gasification or combustion. The heat generated by incineration can be used to generate electricity if the amount is large, and only can be used for heating water or producing steam if the amount is small.

Fig: Biomass liquefication via Pyrolysis

It is the process of thermal conversion of organic matter using a catalyst in the absence of oxygen. The process is used heavily in the chemical industry, for example, to produce ethylene, many forms of carbon, and other chemicals from petroleum, coal, and even wood, to produce coke from coal. The process typically occurs at temperatures above 430 °C (800 °F) and under pressure. It simultaneously involves the change of physical phase and chemical composition and is an irreversible process. However, as it is practically not possible to achieve an oxygen-free environment, a small amount of oxidation always occurs in any pyrolysis system.

Pyrolysis based biorefineries have great potential to convert waste such as plastic and biomass waste into energy and other valuable products, to achieve maximum economic and environmental benefits. Aspirational applications of pyrolysis would convert biomass into syngas and biochar, waste plastics back into usable oil, or waste into safely disposable substances. Pyrolysis processing is one of several options for solid waste resource recovery in space. It has the advantage of being relatively simple and adaptable to a wide variety of feedstocks and it can produce several usable products from typical waste streams.