The construction of a reinforced concrete masonry wall involves the assembly of masonry components such concrete blocks or bricks, mortar, reinforcement, and occasionally grout, which is a type of soupy concrete. Following are the types of materials used in reinforced concrete masonry walls construction:

- Concrete masonry units

- Mortar

- Grout

- Steel reinforcement

Properties of Concrete Masonry Units for Reinforced Concrete Masonry Walls

ASTM C90 (Standard Specification for Loadbearing Concrete Masonry Units) regulated the properties of concrete masonry units. The ASTM C90 covers both solid and hollow masonry units comprised of Portland cement, water, and mineral aggregates. The face shell and web minimum thickness restrictions of hollow concrete masonry units depend on the thickness of the masonry wall.

Moreover, compressive strength of concrete masonry unit specified as 13.1 MPa which is an average for three units and minimum of 11.72 MPa for single unit. For example, if compressive strength of three units were 12 MPa, 13 MPa, and 13.85 MPa respectively, then the test would not be acceptable and fail because the average compressive strength is 12.95 MPa which is below 13.1 MPa.

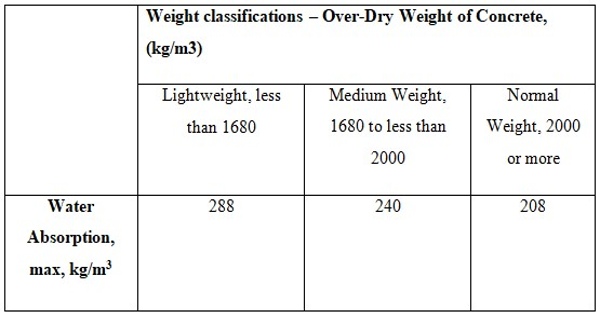

Additionally, it is rare to specify a compressive strength higher than the minimal number because doing so will affect the availability and cost of units with higher strengths. According to the ASTM C90 specification, walls made of such concrete masonry units should not experience dry shrinkage greater than 0.065 percent to prevent the development of shrinkage cracks. Another limitation that the ASTM C90 determined is water absorption of concrete masonry units and it is provided in Table-1. The table shows that compared to medium and normal units, more absorption is permitted for lightweight units because their aggregates absorb more water.

Properties of Mortar for Reinforced Concrete Masonry Walls

Concrete masonry units are kept apart and kept together at the same time by mortar. Typically, there is 9.5 mm of mortar between each unit, although this can be changed to allow for differences in the dimensions of the concrete masonry; this helps the mortar hold the units apart.

Additionally, mortar creates a link between concrete masonry units, producing both flexural and direct tensile strength, and holds them together. Tensile strength may not be as important for the wall in reinforced concrete masonry as it is in unreinforced masonry, but it is still important. Face shell is set with a horizontal junction, known as a bed joint, and mortar is only applied to the face shell and not the webs.

Additionally, vertical joints are known as head joints, and mortar is poured into the head joints on both sides of the wall to a depth equal to the thickness of the face shell.

Standard Specification for Mortar for Unit Masonry (ASTM C 270), governs mortar that is used in the construction of reinforced masonry wall and the ASTM C 270 specifies three cementitious systems namely masonry cement, cement and lime, and mortar cement.

Masonry cements are a blend of Portland or other cements, plasticizing agents, fillers, and other components designed to enhance mortar performance. Sand, hydrated lime, water, and occasionally admixtures are combined with cement, such as Portland cement or mixed cement, to create cement-lime mortar.

Because other forms of mortars lack the added flexural bond strength that mortar cement has, it is the most preferred type of mortar. Because of this, it can be used in seismically active areas, such as those with seismic design categories D and higher. This application is not allowed for other types of mortar. ASTM C 270 classified mortars into M, S, N, O types and the strongest type is M then others respectively. The type of mortar used in the construction of majority of reinforced masonry wall is either Type S or Type N. additionally, Type S or Type M is applied in the seismic category D or higher.

Last but not least, mortars are only divided into two categories: proportion and property. In the event that the designer does not decide on the classification of the mortar, categorizing mortars by percentage is the default.

Properties of Grout for Reinforced Concrete Masonry Walls

ASTM C 476, Standard Specification for Grout for Masonry, govern gouts employed in reinforced concrete masonry walls. Cement, water that may or may not contain lime, sand, coarse aggregate, or admixtures are the ingredients that make up masonry grout. Application of grout is most commonly done to bond concrete masonry units to the steel reinforcement. The remaining hollow space in the masonry unit cell, which is around 100 mm2, is then filled with grout before the steel reinforcement is fitted.

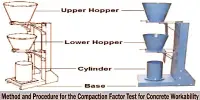

The absorptive nature of masonry units requires that grout have a higher slump than concrete. When grout is poured into a masonry cell, suction causes the mixture to dry out. If the grout is not soupy when pouring begins, the space in masonry cells will not fill properly.

Lack of this hue after grouting may be a sign that the grout has not penetrated to the bottom of the masonry units since water absorption may be seen on the side of masonry units where its color changes to grey. The droop of the grout should be between 20 and 28 cm for placement.

Although the grout slump may appear to be excessive, the site engineer should be aware that it is necessary to pour the grout appropriately. After being placed, the mixture will quickly lose water and become more stronger. Finally, proper vibration equipment is applied to compact the grout.

Properties of Steel Reinforcement for Reinforced Concrete Walls

The same steel reinforcement that is utilized in other reinforced concrete projects is also employed to build reinforced concrete masonry walls. Joint steel bars as per ASTM A 951, is exclusive to masonry and it is galvanized to be protected against corrosion. Joint reinforcement’s primary function is to manage shrinkage cracks. In the concrete masonry cell, steel bars are put vertically, and it is recommended that spacers be used to position the bars precisely.

The reinforcement is added in the middle of the unit by being laid out in a single layer. The masonry units may additionally have steel reinforcing on one side. For instance, when soil acts as a lateral load on a reinforced masonry wall or when wind loads are present but the wall is not subject to wind suction. In either scenario, the designer must be careful to arrange the steel bars correctly. In seismic locations, two layers of reinforcement can be employed for walls that are at least 30 cm thick. Last but not least, reinforcement might be positioned horizontally, as in the case of walls that span between masonry columns that are embedded in the walls.