The workability test for concrete that is carried out in a lab is called the compaction factor test. The ratio of the weights of partially compacted to fully compacted concrete is known as the compaction factor. It was created by the Road Research Laboratory in the UK and is used to assess the concrete’s workability. For concrete that is difficult to work with and for which the slump test is ineffective, the compaction factor test is utilized.

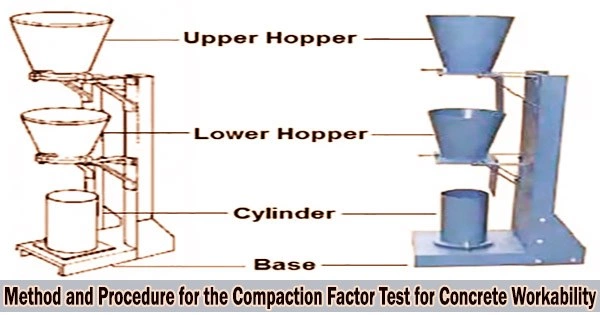

Apparatus

Compaction factor apparatus consists of trowels, hand scoop (15.2 cm long), a rod of steel or other suitable material (1.6 cm diameter, 61 cm long rounded at one end ) and a balance.

Sampling

Concrete mix is prepared as per mix design in the laboratory.

Procedure of Compaction Factor Test on Concrete

- Using the hand scoop, carefully and levelly place the concrete sample in the higher hopper until it is full.

- Cover the cylinder.

- To let concrete fall into the lower hopper, open the trapdoor at the bottom of the upper hopper. Push the concrete sticking on its sides gently with the road.

- Open the trapdoor of the lower hopper and allow the concrete to fall into the cylinder below.

- Cut of the excess of concrete above the top level of cylinder using trowels and level it.

- Clean the outside of the cylinder.

- Weight the cylinder with concrete to the nearest 10 g. This weight is known as the weight of partially compacted concrete (W1).

- Fill the cylinder with the same concrete mix in layers that are each about 5 cm deep, ramming each layer hard to achieve complete compaction.

- Level the top surface.

- Weigh the cylinder with fully compacted. This weight is known as the weight of fully compacted concrete (W2).

- Find the weight of empty cylinder (W).

Note:

The test is sensitive enough to allow for the measurement of differences in workability resulting from the initial hydration process of cement. If strictly similar findings are to be obtained, each test should be conducted at a set interval of time following the mixing.

Two minutes after the mixing process is complete has been shown to be the most practical period for releasing the concrete from the higher hopper.

Calculation of Compaction Factor Value

The weight of partially compacted concrete divided by the weight of fully compacted concrete is known as the compaction factor. The second decimal place should typically be reported to the nearest whole number.

Compaction Factor Value= (W1-W) / (W2-W)

Result of Compaction Factor

Compaction factor of the concrete = The Compaction factor values ranges from 0.7 to 0.95.