In general, masonry is extremely strong in compression but somewhat weak in tension, which is the reason for its limited application in structural members that are subject to tension force.

Additionally, the limitation on the usage of masonry can be overcome by adding strengthened or prestressed bars. By delivering compressions in advance at the necessary degree to act in opposition to the tension that the masonry is subjected to under service loads, prestressed masonry may be created.

Advantages of Prestressed Masonry compared with Reinforced Masonry

Effective Application of Materials

As is well knowledge, the region above the neutral axis of reinforced masonry is active and efficient against the applied moment. Additionally, low strain in the steel reinforcement must be maintained to control cracks and keep them within an acceptable range, which prevents the use of the maximum capacity of high tensile steel bars.

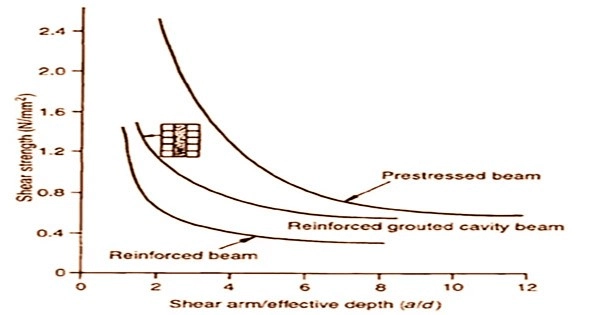

Increased Shear Strength of Prestressed Masonry

Prestrained tendons have a bigger impact on shear strength than reinforcement bars do. Figure-4, which depicts the shear strength of prestressed and reinforced brickwork beams in relation to the shear arm to effective depth ratio, can help to better explain this. As can be observed, the reinforced grouted brickwork cavity beam and the reinforced brickwork beam have shear strengths that are significantly lower than the fully prestressed brickwork beam with bonded tendons. Although it could be argued that this statement only applies to brickwork beams, it is true of other masonry flexural parts as well.

Enhanced Service and Overload Behavior

If the proper amount of prestressing is used, it is possible to manage both cracks and deflection in prestressed brickwork. Additionally, comprehensive prestressing of the element increases the likelihood that cracking and deflection under service load conditions will be completely avoided.

Additionally, overloading-related cracks are all but eradicated. High resistance to fatigue: Because the strain in prestressed steel is so small when applied loads are changed, prestressed masonry offers high resistance to fatigue.

Prestressed Masonry Prestressing Methods

There two techniques which are used for prestressing and they are similar to those of prestressed concrete:

Pre-Tensioning Technique

To a certain extent, tendon strain is applied between external anchorages. The tendons are carefully loosened after the brickwork and the infill material are strong enough. Through the bond between the masonry and its infill material, the forces in the tendons are transferred to the infill material in this process before being transferred to the masonry itself.

Post-Tensioning Technique

Tendons are tensioned by employing appropriate techniques, such as jacking against masonry, once the masonry has reached a certain level of strength. Either an external bearing plate or anchorage blocks embedded in concrete transmit forces from tendons to brickwork.

Additionally, there are instances where the tendon’s stress is distributed across a solid steel plate by threaded nuts bearing on steel washers, which are attached to the masonry. Tendons can be bonded or unbonded, and protection of tendons via grouting or other methods is indicated to increase durability. This technique is ideal for brick construction and is remarkably straightforward and simple to use in actual use.

It is advantageous to vary the prestressing force eccentricity along the length of the masonry flexural member; for example, it is preferable to supply the most eccentricity at the support and zero eccentricity at the middle of a simply supported beam, where the applied moment is greatest.

Additionally, the use of clay bricks may be limited unless specific clay brick units are formed to fit cable profiles to accommodate the applied bending at various sections. This is because low level prestressing, which withstands tensile stress in the wall caused by wind load, and high level prestressing elements, which carry loads due to bending, such as retaining walls and beams, are of small to medium span.

Applications of Prestressed Masonry

In addition to requiring less steel tendons than traditional masonry reinforcement, prestressing masonry is also likely to speed up construction because it uses less grout. The price of installation may partially offset this cost reduction. Various applications of prestressed masonry are provided in the following sections:

- Prestressing masonry can used to construct tilt up walls for slender wall.

- Prestressed masonry shear walls can be used in low seismic areas as it is recommended by the Unites States codes.

- For walls with one or two stories, prestressed masonry is a great choice. In addition to being used for the parking structure’s façade, it is ideal for tall-wall buildings, warehouses,

- In addition to being used to build structures, prestressing masonry is also utilized to reinforce and restore masonry structures that have deteriorated.

Cutting a hole in the wall, installing steel, and then pouring gouts are all steps in the traditional masonry strengthening process. On the other hand, this wall was fortified with fewer openings and no grout. The structural problems brought on by the top final members’ excessive height and slenderness were removed. To reinstall these elements to the walls below, prestressing was used.