Indium tin oxide (ITO) is a ternary composition of indium, tin and oxygen in varying proportions. Depending on the oxygen content, it can be described as either a ceramic or an alloy. It is a widely used material, typically composed of indium oxide (In₂O₃) and tin oxide (SnO₂) in a specific ratio. It is most commonly employed in applications where transparent conductive films are needed.

Indium tin oxide is one of the most widely used transparent conducting oxides, not just for its electrical conductivity and optical transparency, but also for the ease with which it can be deposited as a thin film, as well as its chemical resistance to moisture.

Properties

Indium tin oxide is typically encountered as an oxygen-saturated composition with a formulation of 74% In, 8% Sn, and 18% O by weight. Oxygen-saturated compositions are so typical that unsaturated compositions are termed oxygen-deficient ITO. It is transparent and colorless in thin layers, while in bulk form it is yellowish to gray. In the infrared region of the spectrum it acts as a metal-like mirror.

- Transparent Conductivity: ITO is unique because it is both transparent to visible light and conductive. This is due to its electronic structure, where the tin doping in indium oxide allows for conductivity while still letting light pass through.

- High Electrical Conductivity: It has excellent electrical conductivity, which is crucial for its use in devices like touchscreens and flat-panel displays.

- Optical Transparency: ITO maintains over 80% visible light transmission, making it suitable for applications that require optical clarity.

- Chemical Stability: ITO is chemically stable, which is important for its longevity in various applications.

Common uses

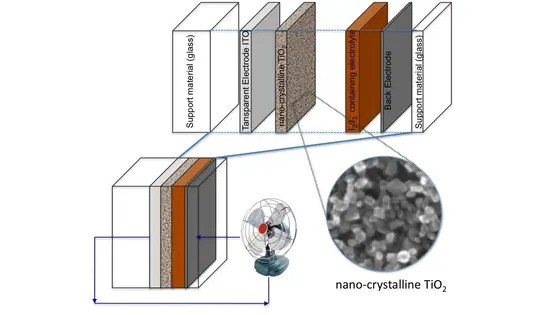

Indium tin oxide (ITO) is an optoelectronic material that is applied widely in both research and industry. ITO can be used for many applications, such as flat-panel displays, smart windows, polymer-based electronics, thin film photovoltaics, glass doors of supermarket freezers, and architectural windows. Moreover, ITO thin films for glass substrates can be helpful for glass windows to conserve energy.

- Touchscreens and Displays: ITO is widely used in the manufacturing of touchscreen panels, flat-panel displays, and OLED (organic light-emitting diode) screens. Its ability to form a transparent conductive layer is vital for the functionality of these devices.

- Solar Cells: ITO is also used in the production of solar cells, particularly in the production of thin-film photovoltaic devices, where it serves as a transparent electrode.

- LEDs: In organic LEDs (OLEDs), ITO is used as a transparent electrode layer.

- Smart Windows: ITO is used in smart windows that can change their transparency in response to light or an electrical current, as in electrochromic or thermochromic windows.

- Sensors: ITO is also used in various sensors, especially those that require a transparent electrode.