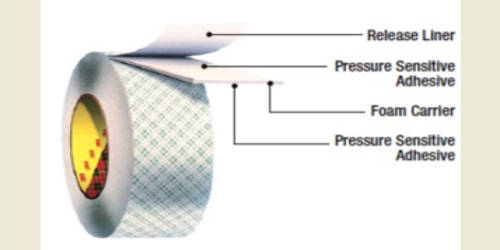

Pressure-sensitive adhesive (PSA, self-adhesive, self-stick adhesive) is a type of non-reactive adhesive which forms a bond when pressure is applied to bond the adhesive with a surface. They ensure that adhesive tape can bond at the slightest of touch. No solvent, water, or heat is needed to activate the adhesive. The combination of various properties makes it effective. It is used in pressure-sensitive tapes, labels, glue dots, note pads, automobile trim, and a wide variety of other products. They are often used to temporarily hold components like gaskets in position during assembly.

As the name “pressure-sensitive” indicates, the degree of a bond is influenced by the amount of pressure that is used to apply the adhesive to the surface. There is a good reason for why it is the pressure-sensitive adhesive that makes adhesive tape sticky. Surface factors such as smoothness, surface energy, removal of contaminants, etc. are also important to proper bonding. They combine viscosity – the state of being thick, sticky, and semifluid in consistency like honey for example – with elasticity – like rubber has for example. They are typically formulated from natural rubber, certain synthetic rubbers, and polyacrylates.

PSAs are usually designed to form a bond and hold properly at room temperatures. They can be adjusted even better to the specific requirements because acrylate consists of synthetic polymers that can be “tailored.” PSAs typically reduce or lose their tack at low temperatures and reduce their shear holding ability at high temperatures; special adhesives are made to function at high or low temperatures. The special feature of pressure-sensitive adhesives is that they do not solidify to form a solid material, but remain viscous

Application

Pressure-sensitive adhesives are designed for either permanent or removable applications. They are used for adhesive tapes and labels. They can be supplied dissolved in organic solvents, as an aqueous dispersion, as a hot melt, or coated on release liner as tape. Examples of permanent applications include safety labels for power equipment, foil tape for HVAC ductwork, automotive interior trim assembly, and sound/vibration damping films. Some high-performance permanent PSAs exhibit high adhesion values and can support kilograms of weight per square centimeter of contact area, even at elevated temperature. And they do their job reliably and highly effectively. These build adhesion to a permanent bond after several hours or days. The adhesive can be coated in a pattern to provide bonded and unbonded areas, e.g. assembly of membrane switches, filter frames.