Hydrogen fuel cell technology is currently being extensively investigated around the world in order to create a dependable sustainable energy source. Global warming, natural disasters, and the scarcity of fossil fuels have focused global attention on environmentally friendly and renewable energy sources. The hydrogen fuel cell technology most emphatically meets those requirements.

A new high-temperature polymer fuel cell that operates at 80-160 degrees Celsius and has a higher rated power density than current fuel cells solves the long-standing problem of overheating, which is one of the most significant technical barriers to using medium- and heavy-duty fuel cells in transportation vehicles like trucks and buses.

Because modern fuel cells operate at 60-80 degrees Celsius, they require big radiators and air intakes to keep cool. To address this issue, scientists at Los Alamos National Laboratory created a novel polymer fuel cell that can run at greater temperatures.

“Fuel cells are energy conversion devices that generate electricity by electrochemically mixing hydrogen and oxygen from the surrounding environment. Fuel cell vehicles, like other electric vehicles, have no tailpipe emissions that contribute to smog or greenhouse gas emissions” said Yu Seung Kim of the Materials Synthesis & Integrated Devices group at Los Alamos. “Moreover, hydrogen may be produced from a variety of domestic resources while emitting no greenhouse gases.”

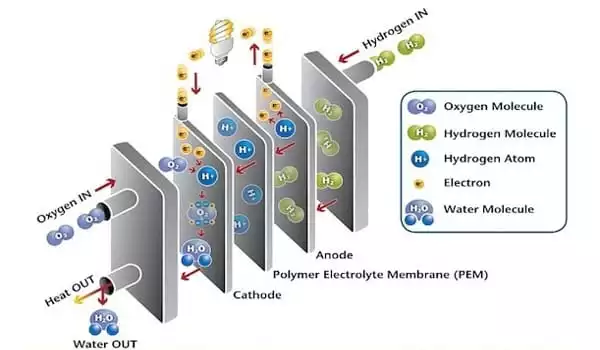

Fuel cells are energy conversion devices that generate electricity by electrochemically mixing hydrogen and oxygen from the surrounding environment. Fuel cell vehicles, like other electric vehicles, have no tailpipe emissions that contribute to smog or greenhouse gas emissions.

Yu Seung Kim

Hydrogen fuel cells are an excellent choice for medium- and heavy-duty on-road transportation, such as trucks and buses, and they also have maritime, rail, and aviation applications. In the face of global warming, carbon pollution, and the depletion of fossil fuels, the hydrogen fuel cell provides an intriguing new platform for addressing both fuel and environmental challenges. In today’s world, there is a high need for hydrogen fuel in the industrial sector. Hydrogen gas can be created using either fossil fuels (coal, gas, petroleum, and so on) or renewable energy sources (solar, wind, geothermal energy, biogas, biomass, etc.).

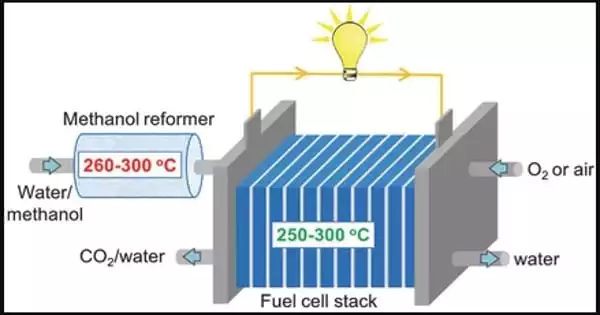

This hydrogen gas has the potential to be a universal fuel that can be produced using any existing fuel source and stored for use at any point in the future. In a fuel cell, electricity is generated by a chemical process between hydrogen and oxygen in which hydrogen gives an electron to the anode via an oxidation reaction and becomes an electron less hydrogen ion known as a proton. This proton moves across the proton exchange membrane and undergoes a reduction process with oxygen, resulting in the creation of water and heat. The electron flow in the external circuit determines the output current load. We can generate power via an electrochemical reaction that emits no toxic chemicals or fumes. That’s why the fuel cell technology is considered to be sustainable and emission-free fuel solution for future demand.

Given global efforts to reduce transportation emissions, the electrification of medium- and heavy-duty transportation – whether with batteries or hydrogen fuel cells – is necessary. In comparison to battery-powered vehicles, fuel cells provide quick filling and sufficient fuel storage for long-range applications. Over several decades, researchers have investigated fuel cells that can run over 100 degrees Celsius, allowing for simpler fuel cell systems through improved heat and water management. While more research is needed to verify the durability required for heavy-duty applications, this study gives a strategy for fabricating highly performing fuel cells in hot and dry circumstances.

Advances to fuel cell technology also support the Intermountain West Energy Sustainability & Transitions (I-WEST) initiative, which is developing a technology roadmap to transition the western United States to an economically sustainable, carbon-neutral energy system. The roadmap will outline ways for the Intermountain West states to meet challenges, capitalize on opportunities, and build an equitable energy transition strategy.

How they work

Phosphoric acid is used as an electrolyte at the electrode in conventional high-temperature polymer electrolyte membrane fuel cells. The Los Alamos researchers created a polymer electrolyte out of a phosphonated polymer and a perfluorosulfonic acid in this study. The scientists discovered that a proton from the perfluorosulfonic acid passes to the phosphonated polymer and greatly increases proton conductivity in this composite electrolyte structure. The researchers were able to attain a nearly 800 milliwatts per square centimeter rated power density of the fuel cell at 160 C by adopting the composite polymer electrolyte, which is a 60% improvement over the phosphoric acid-based fuel cells.