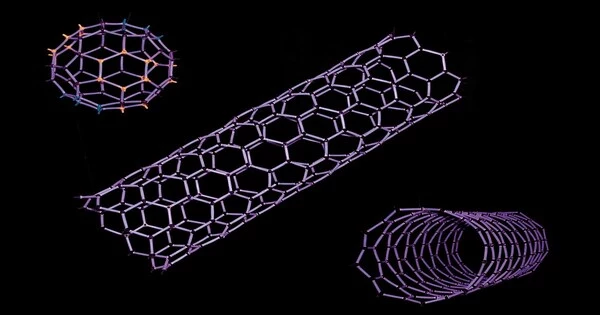

Carbon nanotube (CNTs) are carbon tubes with diameters in the nanometer range (nanoscale). These are cylindrical structures made of carbon atoms stacked in a hexagonal lattice, similar to how graphene sheets are made. They are a type of carbon allotrope. Because of their extraordinary features and prospective uses in sectors including nanotechnology, materials science, electronics, and even medicine, they are one of the most well-known and intensively studied nanomaterials.

Structure

Carbon nanotubes are essentially rolled-up graphene sheets. They can be single-walled (SWCNT) or have many concentric layers, resulting in multi-walled carbon nanotubes (MWCNT).

Single-walled carbon nanotubes (SWCNTs) have diameters ranging from 0.5 to 2.0 nanometers, which is approximately 100,000 times smaller than the breadth of a human hair. They can be envisioned as cutouts from a two-dimensional graphene sheet that has been rolled up to form a hollow cylinder. MWCNTs are multi-walled carbon nanotubes made up of nested single-wall carbon nanotubes in a tube-in-tube arrangement. MWCNTs with two or three walls are special examples of MWCNTs.

Production Methods

CNTs can be synthesized through various methods, including chemical vapor deposition (CVD), arc discharge, and laser ablation. Each method has its advantages and limitations in terms of yield, purity, and control over properties.

Types:

- Single-Walled Carbon Nanotubes (SWCNTs): These consist of a single layer of carbon atoms rolled into a tube. SWCNTs can have different chiralities, which affect their electrical and optical properties.

- Multi-Walled Carbon Nanotubes (MWCNTs): These comprise multiple layers of graphene rolled into nested cylinders. MWCNTs are generally stronger and more thermally stable than SWCNTs.

Properties:

Carbon nanotubes can exhibit remarkable properties, such as exceptional tensile strength and thermal conductivity because of their nanostructure and strength of the bonds between carbon atoms. Some SWCNT structures exhibit high electrical conductivity while others are semiconductors.

- Exceptional strength: CNTs are incredibly strong and have one of the highest tensile strengths of any known material.

- Excellent thermal conductivity: They exhibit high thermal conductivity, making them useful in applications like thermal management and heat dissipation.

- Electrical properties: SWCNTs can be either metallic or semiconducting depending on their chirality, making them attractive for electronic applications.

- Lightweight: CNTs are very lightweight, despite their strength.

Applications:

- Electronics: CNTs have potential applications in nanoscale electronic devices, such as transistors, interconnects, and sensors.

- Materials: They can be used to enhance the mechanical and electrical properties of composites and materials.

- Energy storage: CNTs have been explored for use in batteries and supercapacitors due to their high surface area and electrical conductivity.

- Nanomedicine: CNTs have been investigated for drug delivery and imaging applications in the field of medicine.

- Nanotechnology: They play a crucial role in nanotechnology research and development.

Challenges

Despite its promise, CNT manufacture and commercialization face hurdles such as scalability, purity, and potential health and environmental risks related with their use and disposal.

Carbon nanotubes can also be chemically changed. These features are projected to be useful in a wide range of technological applications, including electronics, optics, composite materials (replacing or supplementing carbon fibers), nanotechnology, and other materials science applications.