Alum (/ˈæləm/), any of a group of double salts hydrated, typically consisting of aluminum sulfate, hydrated water, and another element of sulfate. Its general formula XAl(SO4)2·12H2O, where X is a monovalent cation such as potassium or ammonium. However, one of the compounds is known to be an alum with the empirical formula AB(SO4)2·12H2O. Some alum, such as sodium alum and ammonium alum are named after the monovalent ion. The hydration of the sulfate of a single charged cation (e.g., K+) and the sulfate of any of a variety of triple charged cations (e.g., Al3+) result in a whole series of hydrated double salts.

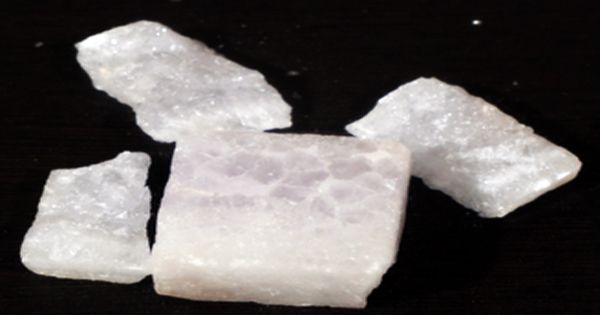

For salts of the same formula and structure, the term ‘alum’ is still used, more commonly, except that aluminium is substituted by another trivalent metal ion such as chromium(III), and/or sulfur is substituted by another chalcogen such as selenium. Alum is often seen in its crystalline form, but it is marketed more commonly as a powder. The term ‘alum’ (or ‘papermaker’s alum’) is used in most industries to refer to aluminum sulphate Al2(SO4)3•nH2O, which is used for most industrial flocculation.

Alum (Crystals)

Potassium aluminum sulfate, ammonium aluminum sulfate, and sodium aluminum sulfate are the most important alums. Sulfate of potassium aluminum, also known as an alum of potassium or alum of potash. As a “deodorant rock” for underarm use, it is often marketed as a large crystal. A significant source of alum replacements in ancient times was the western desert of Egypt. These evaporites were mainly FeAl2(SO4)4·22H2O, MgAl2(SO4)4·22H2O, NaAl(SO4)2·6H2O, MgSO4·7H2O, and Al2(SO4)3·17H2O.

Alums can easily be formed from an aqueous solution by precipitation. For instance, aluminum sulfate and potassium sulfate are dissolved in water when processing potassium alum, and then the alum crystallizes out of the solution after evaporation. On the island of Lesbos, the development of potassium alum from Alunite is archaeologically attested. In the 7th century, this site was abandoned but dates back at least to the 2nd century CE. Treating bauxite ore with sulfuric acid and then with potassium sulfate is a more common processing process.

In the Islamic middle ages, alum was the most popular mordant used in the dye industry. It was the Chad region’s largest export, from where it was exported to the markets of Egypt and Morocco, and then to Europe. In Egypt and Yemen, other, less important, sources have been identified. Evaporation of a water solution containing ammonium sulfate and aluminum sulfate produces ammonium alum. It can also be obtained by using ammonia to treat a mixture of aluminum sulfate and sulfuric acid. The most significant alums are made industrially from potassium, sodium, and ammonium. Typical recipes require the combination of aluminium sulfate and monovalent cation sulfate. Aluminium sulfate is typically obtained by treating sulfuric acid with minerals such as alum schist, bauxite, and cryolite.

In different minerals, alums occur naturally. For example, potassium alum is present in the minerals kalinite, alunite, and leucite, which can be processed to obtain alum crystals with sulfuric acid. It is also used as a flocculant in water purification, as an ingredient in aftershave, and as a preparation for fireproof textiles in leather tanning. Ammonium alum is used in tanning, textile dyeing, flame retardant textiles, porcelain cement and vegetable glue processing, water purification, and some deodorants.

Each metal ion in the alum is surrounded by six water molecules. They liquefy when heated, and if the heating continues, the crystallization water is forced out the salt froths and swells, and an amorphous powder eventually remains. There is an astringent and acid taste in most alum. They are odorless, colorless, and exist as a crystalline white powder. Alums are normally soluble in hot water, and they can be readily precipitated to form large octahedral crystals from aqueous solutions. The water solubility of the different alums varies greatly, with sodium alum being readily soluble in water, while caesium and rubidium alum are only partially soluble in water.

Alum has many industrial and household applications. Potassium alum is used most commonly, but for many of the same purposes, ammonium alum, ferric alum, and soda alum-are used.

Uses of Alum

- purification of drinking water as a chemical flocculant

- in styptic pencil to stop bleeding from minor cuts

- the adjuvant in vaccines ( a chemical that enhances the immune response)

- deodorant “rock”

- pickling agent to help keep pickles crisp

- flame retardant

- the acidic component of some types of baking powder

- an ingredient in some homemade and commercial modeling clay

- an ingredient in some depilatory (hair removal) waxes

- skin whitener

- ingredient in some brands of toothpaste

There are different industrial uses of this chemical. Alum and animal glue were dissolved in water in traditional Japanese art, creating a liquid known as dousa (ja:礬水), and used as an undercoat for sizing paper. In water purification plants, aluminum hydroxide adsorbs suspended particles from the water and is thus a useful flocculating agent. It fixes dye on cotton and other fabrics when used as a mordant (binder) in dyeing, making the dye insoluble. In general, as the alkali metal atom is larger, alums are formed more readily. Alums are also used in medicine for pickling, baking powder, fire extinguishers, and as astringents.

Information Sources: