Since scientists work to find and create new functional materials with desirable qualities that are suitable for a wide range of applications, materials science is a field of study that is continually changing.

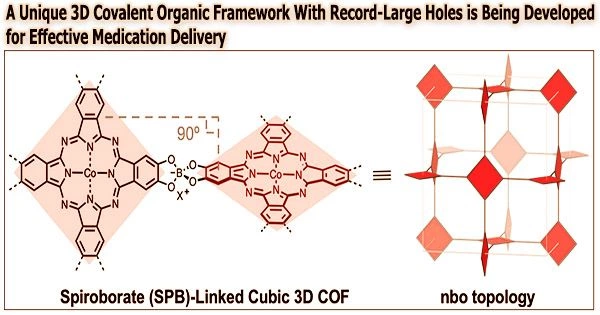

Covalent organic frameworks (COFs), a type of materials distinguished by crystalline porous polymers connected in the form of a network by covalent bonds, provide one example on this front.

COFs can be constructed for a variety of applications including gas storage and separation, catalysis, and drug administration due to their structural diversity, high porosity, and conveniently accessible active sites.

Despite their enormous potential, most reported COFs have limited pores because interpenetrated frameworks emerge during the building process, creating tightly woven interlaced structures with constrained pore sizes.

Moreover, most research so far has focused on 2D COFs given the difficulty of constructing a 3D, non-interpenetrated COF with large pore sizes.

Now, in a new study published in Angewandte Chemie, researchers from Zhejiang Normal University, China and Tokyo University of Science (TUS), Japan have reported a novel 3D COF with the largest pore size and lowest density ever recorded.

TUS-64 shows all the desirable qualities of a drug delivery vehicle, such as controlled release kinetics, sustained delivery, and site-specific targeting.

Professor Yuichi Negishi

The team, led by Professor Yuichi Negishi from TUS and including contributions from Dr. Saikat Das from TUS and Professor Teng Ben from Zhejiang Normal University, has achieved this feat by reticulating a 6-linked triptycene linker and a 4-linked porphyrin linker to form a non-interpenetrated network, resulting in the unprecedented pore size and density.

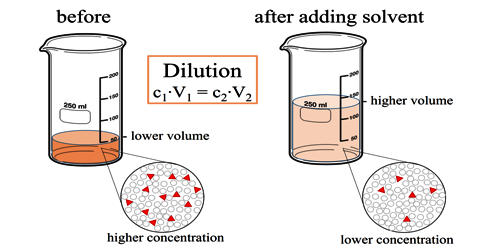

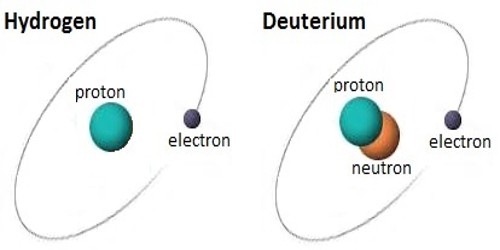

The material, which the team named TUS-64, was constructed by linking two specific building units: a 2,3,6,7,14,15-hexakis(4′-formylphenyl)-triptycene (HFPTP) as a 6-linked linker and a 5,10,15,20-tetrakis(4-aminophenyl)porphyrin (TAPP) as a 4-linked linker. The two linkers were combined in a solvent at a high pressure and temperature using a technique known as solvothermal condensation.

TUS-64 displayed a structure resembling a honeycomb with pores of 4.7 nm in size and a record-low density of 0.106 g/cm3 (water has a density of 1 g/cm3). The substance, while having a fragile appearance, was found to be tough, resisting breakdown in both organic and inorganic solvents as well as temperatures of up to 400°C.

The material is perfect for holding and transporting visitor molecules due to its highly interconnected mesoporous structure and great stability. The team placed five different medications into the material’s pores and observed their release in a phosphate buffer solution that mimicked human bodily fluid to examine the potential of TUS-64 as a drug delivery system.

The drugs included captopril (for hypertension and heart failure), ibuprofen (for fever and pain), isoniazid (for tuberculosis), 5-fluorouracil (for cancer), and brimonidine (for glaucoma).

TUS-64 demonstrated a strong ability to store the medications in all cases and a sustained release rate, making it appropriate for delivering drugs over prolonged periods of time.

“TUS-64 shows all the desirable qualities of a drug delivery vehicle, such as controlled release kinetics, sustained delivery, and site-specific targeting,” highlights Prof. Negishi, excited.

New methodologies and procedures for creating 3D COFs with desirable properties, like the one presented in this paper, could impact a wide range of industries and even people’s lives with TUS-64 as a possible game changer for many applications.

“By making use of these characteristics of COFs, we could create new materials that will be required in the next generation society, such as drug delivery vehicles, energy and environmental materials, and separation materials,” concludes Prof. Negishi.