A rechargeable lithium-ion battery in the shape of an ultra-long fiber that might be woven into garments has been developed by researchers. The battery could power a wide range of wearable electrical devices and could potentially be used to create 3D-printed batteries in almost any shape.

The researchers anticipate new possibilities for self-powered communications, sensing, and computational gadgets that can be worn like regular clothing, as well as devices whose batteries can also serve as structural components.

In a proof of concept, the team behind the new battery technology has produced the world’s longest flexible fiber battery, 140 meters long, to demonstrate that the material can be manufactured to arbitrarily long lengths. The work is described in the journal Materials Today. MIT postdoc Tural Khudiyev, former MIT postdoc Jung Tae Lee, and Benjamin Grena SM ’13, Ph.D. ’17 are the lead authors of the paper. Other co-authors are MIT professors Yoel Fink, Ju Li, and John Joannopoulos, and seven others at MIT and elsewhere.

Previously, researchers, including members of this team, exhibited fibers with a wide range of electronic components, such as light-emitting diodes (LEDs), photosensors, communications, and digital systems. Many of these are wearable and washable, making them suitable for use in wearable products, although they have all relied on an external power supply thus far. Now, this fiber battery, which is both wearable and washable, has the potential to make such gadgets totally self-contained.

When we embed the active materials inside the fiber, that implies that sensitive battery components already have a good sealing, and all the active materials are very well-integrated, so they don’t change their position” during the drawing process.

Tural Khudiyev

The new fiber battery is made with innovative battery gels and a standard fiber-drawing technology that begins with a bigger cylinder holding all of the components and warms it to just below its melting point. The material is drawn through a narrow hole, compressing all of the components to a fraction of their original diameter while retaining all of the original part arrangement.

Others have attempted to make batteries in fiber form, according to Khudiyev, but those were structured with key materials on the outside of the fiber, whereas this system embeds the lithium and other materials inside the fiber, with a protective outside coating, making this version directly stable and waterproof. According to him, this is the first demonstration of a sub-kilometer-long fiber battery that is both sufficiently long and highly robust for practical uses.

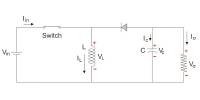

The fact that they were able to create a 140-meter fiber battery demonstrates this “The length has no evident upper limit. We could certainly do kilometer-scale length, “he claims. A demonstration device including the novel fiber battery includes a “Li-Fi” communications system – one in which light pulses are used to transfer data – as well as a microphone, pre-amp, transistor, and diodes to build an optical data link between two woven fabric devices.

“When we embed the active materials inside the fiber, that implies that sensitive battery components already have a good sealing,” Khudiyev explains, “and all the active materials are very well-integrated, so they don’t change their position” during the drawing process. Furthermore, the resulting fiber battery is much thinner and more flexible, with an aspect ratio, or length-to-width fraction, of up to a million, far exceeding other designs, making it feasible to use standard weaving equipment to create fabrics that incorporate batteries as well as electronic systems.

According to him, the 140-meter fiber manufactured thus far has an energy storage capacity of 123 milliamp-hours, which may charge smartwatches or phones. The fiber device is only a few hundred microns thick, making it thinner than earlier attempts to manufacture fiber-based batteries.

“The beauty of our technique is that we can embed many devices in a single fiber,” Lee explains, contrasting with other approaches that require the integration of different fiber devices. They demonstrated the integration of an LED and a Li-ion battery in a single fiber, and he believes that in the future, more than three or four devices can be merged in such a small space. “When we combine these multi-device fibers, the aggregate will accelerate the realization of a compact fabric computer.”

Aside from individual one-dimensional threads that can be weaved to generate two-dimensional fabrics, the material can also be utilized in 3D printing or custom-shape systems to construct solid items, such as casings that could supply both the structure and power source of a gadget. To illustrate these capabilities, a toy submarine was wrapped with battery fiber and powered. Incorporating the power source into the framework of such devices could reduce overall weight and thus improve efficiency and range.

“This is the first time a fiber battery unit has been 3D printed,” Khudiyev explains. “If you want to construct sophisticated objects” that contain a battery device using 3D printing, he argues, this is the first technology that can do so. “You don’t need to add anything else after printing because everything, including the metals and active components, is already inside the fiber. It’s a one-step printing process. That’s a first for me.”

This means that “computational units can now be installed within commonplace devices, including Li-Fi,” he explains. The team has already submitted for a patent on the technique and is working on future improvements in power capacity and material changes to boost efficiency. According to Khudiyev, such fiber batteries could be ready for usage in commercial devices in a few years.

The research was funded by the National Science Foundation’s MIT MRSEC program, the US Army Research Laboratory’s Institute for Soldier Nanotechnologies, the National Science Foundation’s graduate research fellowship program, and the National Research Foundation of Korea.