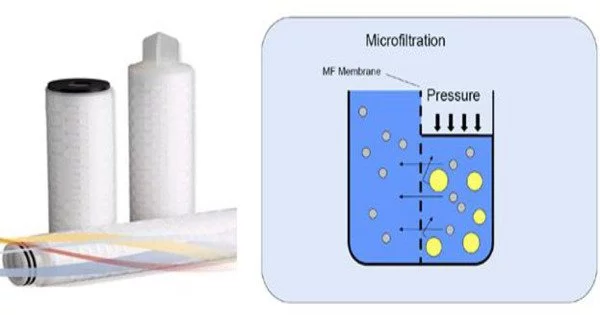

Microfiltration is a physical filtration process that involves passing a contaminated fluid through a special pore-sized membrane filter to separate microorganisms and suspended particles from the process liquid. It is frequently used in conjunction with other separation processes such as ultrafiltration and reverse osmosis to provide a product stream free of unwanted contaminants.

It is a filtration process that uses a membrane to separate particles and microorganisms from a liquid or gas. The membrane has a pore size typically ranging from 0.1 to 10 micrometers, which is smaller than those used in ultrafiltration and reverse osmosis, but larger than those used in nanofiltration. The process is commonly used in industries such as biotechnology, food and beverage, and water treatment.

General principles

Microfiltration is commonly used as a pre-treatment for other separation processes like ultrafiltration and as a post-treatment for granular media filtration. The typical particle size for microfiltration is between 0.1 and 10 μm. In terms of approximate molecular weight, these membranes are capable of separating macromolecules with molecular weights less than 100,000 g/mol.

In microfiltration, the liquid or gas to be filtered is passed through the membrane under pressure, while the larger particles and microorganisms are retained on the surface of the membrane. The filtered liquid or gas, called permeate, passes through the membrane and is collected on the other side, while the retained particles and microorganisms, called retentate, are discharged from the system.

The filters used in the microfiltration process are specially designed to prevent particles such as, sediment, algae, protozoa or large bacteria from passing through a specially designed filter. More microscopic, atomic or ionic materials such as water (H2O), monovalent species such as Sodium (Na+) or Chloride (Cl−) ions, dissolved or natural organic matter, and small colloids and viruses will still be able to pass through the filter.

The suspended liquid is passed through at a relatively high velocity of around 1-3 m/s and at low to moderate pressures (around 100-400 kPa) in a sheet or tubular form parallel or tangential to the semi-permeable membrane. To allow the liquid to pass through the membrane filter, a pump is commonly installed on the processing equipment. There are also two pump configurations: pressure-driven and vacuum driven. To measure the pressure drop between the outlet and inlet streams, a differential or regular pressure gauge is commonly attached.

Microfiltration membranes are most commonly used in the water, beverage, and bio-processing industries. The recovery rate of the exit process stream after treatment with a micro-filter is typically in the 90-98% range.

Microfiltration is an effective way to remove suspended solids, bacteria, and other microorganisms from a liquid or gas, while leaving the desired components of the fluid stream intact. It is also used in the clarification of fruit juices and wine, the removal of bacteria from milk and dairy products, and the purification of pharmaceuticals and biotechnology products.