An important new study conducted by researchers at the United States Department of Energy’s (DOE) Argonne National Laboratory has yielded critical new insights into the lithium production process and how it relates to long-term environmental sustainability, particularly in the area of transportation with batteries and electric vehicles.

The paper, “Energy, Greenhouse Gas, and Water Life Cycle Analysis of Lithium Carbonate and Lithium Hydroxide Monohydrate from Brine and Ore Resources and Their Use in Lithium-Ion Battery Cathodes and Lithium-Ion Batteries,” published in the journal Resources, Conservation & Recycling, was the result of a unique collaboration with SQM, a Chilean company that is one of the world’s largest lithium producers.

According to Argonne lifecycle analyst and lead author Jarod Kelly, the researchers discovered, using operational data supplied by SQM, that the sourcing of lithium, both from a process and location standpoint, can have a significant impact on its associated environmental impacts.

“The results show that depending on the resource allocation method used, concentrated lithium brine and its related end products can vary significantly in terms of energy consumption, greenhouse gas emissions, sulfur dioxide emissions, and water consumption,” Kelly explained.

A new study has yielded critical fresh insights into the lithium production process and how it relates to long-term environmental sustainability, particularly in the area of transportation with batteries and electric vehicles.

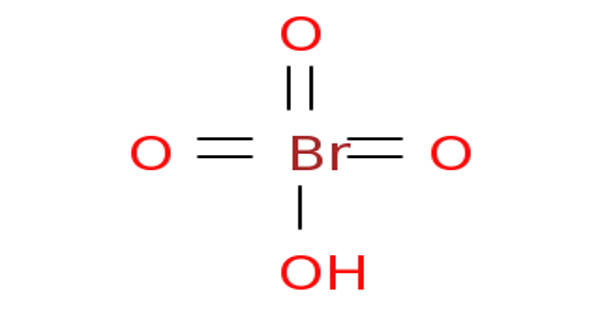

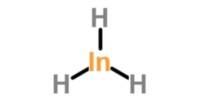

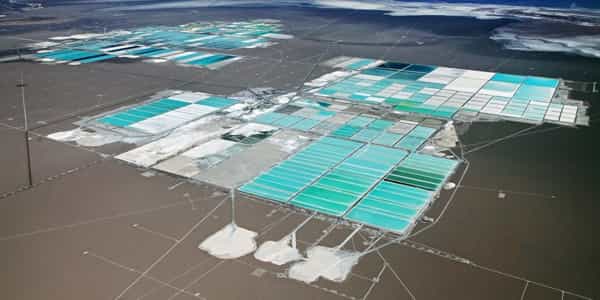

The brine-based lithium extracted from the Salar de Atacama, a large salt flat in northern Chile near the Andes Mountains, was modeled by the researchers. Natural drying of lithium takes place in large ponds to evaporate the water, concentrate the lithium, and remove impurities. Later, materials and energy are added to create lithium carbonate and lithium hydroxide. These two end products are shipped all over the world to battery cathode manufacturers, who then process them into a variety of battery materials.

The findings of the study could have significant implications for how to optimize lithium production at each stage of the process, resulting in more environmentally friendly products, particularly battery electric vehicles. According to the International Energy Agency, demand for lithium could increase by up to 40 times between 2020 and 2040, owing primarily to the global deployment of electric vehicles.

“Examination of current lithium production and pursuit of future production, including from within the United States,” said Michael Wang, director of Argonne’s Systems Assessment Center and study co-author.

“This research establishes a baseline for current practices and identifies potential areas for improvement,” Kelly added. “With additional research, this information could be used to help develop best practices for producing lithium in the most sustainable way.”

SQM approached Argonne last year about collaborating to support the company’s recently announced ambitious sustainability goals. “According to our sustainability plan,” said Veronica Gautier, SQM’s head of innovation, “we want to look more closely at carbon emissions, water consumption, and energy consumption in our lithium products, and see how it affects the rest of the value chain.” “This information will assist us in meeting our goal of becoming carbon neutral by 2030.”

According to Wang, the analysis will also help answer an overarching question in the global trend toward electrification of transportation with battery electric vehicles. “Electrification is frequently used to pursue environmental sustainability. But before we can say we are truly on a sustainable path, we need to learn more about lithium battery production “He stated. “This research provides critical insights into the value chain of electric mobility.”

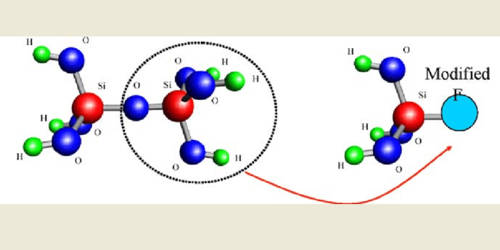

Argonne’s open-source modeling tool, GREET (Greenhouse Gas Regulated Emissions and Energy in Technologies), was used in the formal analysis, with detailed data and technical insight provided by SQM. The researchers supplemented their data with ore-based lithium extracted from spodumene ore in Western Australia, in addition to brine-based lithium extracted in Chile.

Kelly stated that it was the first analysis of its kind that was based on such extensive data from an industrial partner. Gautier went on to say that SQM was pleased that the study’s findings were now public and that they would contribute to global efforts to ensure responsible and sustainable lithium production.

“It’s critical for us to have complete transparency about how our process works, and we’re excited to draw on Argonne’s experience and expertise,” she said. “Sharing this information will be extremely beneficial to education.”