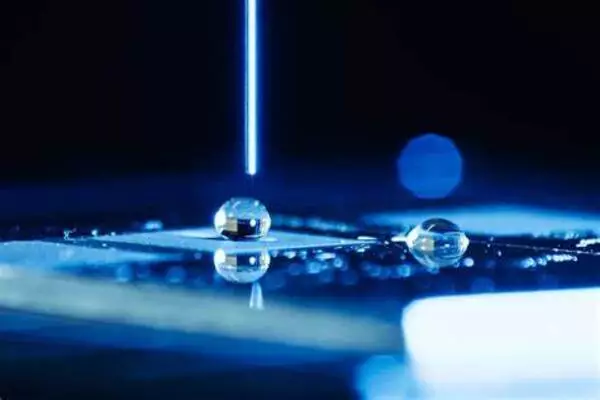

In a report published in Nature Chemistry, researchers disclose a new technique for making water droplets glide off surfaces. The discovery calls into question previously held beliefs regarding friction between solid surfaces and water, as well as opening up a new path for researching droplet slipperiness at the molecular level. The novel technology has a wide range of applications, including plumbing, optics, and the automotive and maritime industries.

Water is constantly interacting with solid objects all around us. Water’s ability to stick to or slide off surfaces has an impact on cooking, transportation, optics, and hundreds of other technologies. Understanding the molecular dynamics of these small droplets can help scientists and engineers enhance a variety of domestic and commercial technologies.

Aalto University professor Robin Ras recently evaluated a topic in Nature Reviews Chemistry on liquid-like surfaces, a new type of droplet-repellent surface that offers significant technological advantages over existing techniques. They have highly mobile molecular layers that are covalently bonded to the substrate, giving solid surfaces a liquid-like property that acts as a lubricant layer between the water droplets and the surface itself. Ras led a team of researchers who utilized a specially built reactor to build a liquid-like layer of molecules on top of a silicon surface known as self-assembled monolayers (SAMs).

Things like heat transfer in pipes, de-icing and anti-fogging are potential uses. It will also help with microfluidics, where tiny droplets need to be moved around smoothly, and with creating self-cleaning surfaces.

Sakari Lepikko

Watching self-assembled monolayers grow

‘Our work is the first time anyone has gone directly to the nanometer-level to produce molecularly heterogeneous surfaces,’ explains lead author and doctorate researcher Sakari Lepikko.

The team was able to fine-tune how much of the silicon surface the monolayer covered by carefully altering parameters such as temperature and water content inside the reactor.

‘I find it really intriguing that we can see the self-assembled monolayers evolve with incredible detail by integrating the reactor with an ellipsometer,’ Ras adds. ‘The results showed that whether SAM coverage was low or high, which is also when the surface is most homogenous, there was increased slipperiness. At low coverage, the silicon surface is the most common component, while at high coverage, SAMs are the most common.’

‘It was counterintuitive that even low coverage yielded exceptional slipperiness,’ Lepikko continues.

Anti-fogging, de-icing, self-cleaning

At low coverage, the water forms a film on the surface, which was thought to increase friction.At low SAM coverage, we discovered that water moves freely between the molecules of the SAM, falling off the surface. When the SAM coverage is high, the water stays on top of the SAM and slides off equally as quickly. Water binds to the SAMs and clings to the surface only between these two states.”

The new technology was extremely effective, as the researchers constructed the world’s slipperiest liquid surface.

The discovery has the potential to have far-reaching ramifications whenever droplet-repellent surfaces are required. According to Lepikko, this includes hundreds of examples ranging from everyday life to industrial solutions.

‘Things like heat transfer in pipes, de-icing and anti-fogging are potential uses. It will also help with microfluidics, where tiny droplets need to be moved around smoothly, and with creating self-cleaning surfaces. Our counterintuitive mechanism is a new way to increase droplet mobility anywhere it’s needed,’ Lepikko says.

The team intends to continue exploring with their self-assembling monolayer structure and to develop the layer itself next. Lepikko is very thrilled about the data this research has offered for future improvements.

‘The fundamental problem with a SAM coating is that it is relatively thin and so easily disperses after physical contact. However, examining them provides us with essential scientific knowledge that we may employ to develop long-lasting practical applications.’

The Soft Matter and Wetting group at the Department of Applied Physics conducted the research using the national research infrastructure OtaNano, which has already generated other pioneering water-repellent materials.