Potato starch is a type of starch extracted from potatoes. It is a fine white powder that is commonly used as a thickening agent in cooking and baking. Potato starch is often used as a gluten-free alternative to wheat flour for people with gluten intolerance or celiac disease. It is also used in the production of processed foods, such as instant noodles, potato chips, and baked goods, as well as in pharmaceuticals and textile industries.

The University of Alicante’s Waste, Energy, Environment and Nanotechnology (REMAN) research group have created a water-soluble plastic material made from potato starch. The UA technology-based company Solublion, which is connected to the Alicante Science Park, will soon sell this material on the market.

Ignacio Martn Gullón, a professor of chemical engineering, claims that this new material has significant advantages over existing materials because it is both compostable and biodegradable, making it appropriate for usage as a flexible film, preferably in bags and packaging.

The creation of this new substance was inspired by Daniel Domene López, the current president and chief executive officer of Solublion, who wrote a thesis on thermoplastic starch for the creation of environmentally sustainable products.

In the event that, due to poor waste management, this new material ends up in natural ecosystems, he hoped it would make a meaningful contribution to reducing the impact caused by the improper management of conventional plastic waste because it does not, at the end of its useful life, create an environmental issue.

Domene López explained that the consumption of worldwide plastic materials before the pandemic was around 370 million metric tons, a figure that they estimate could exceed 400 million in the coming years due to the increase in packaging and single-use materials.

Only two million of these, prior to the pandemic, were biodegradable polymers, but by the end of the decade, customers are expected to desire eight million tons of these materials.

The plastic developed by the REMAN group is highly stable and has a low migration rate. According to Ignacio Martn, the group’s solutions are meant to be used as a direct substitute for current options in the packaging and single-use plastics industries.

Additionally, thanks to their proprietary technology, they can offer a variety of mechanical performances, allowing them to customize their products to meet the needs of their clients.

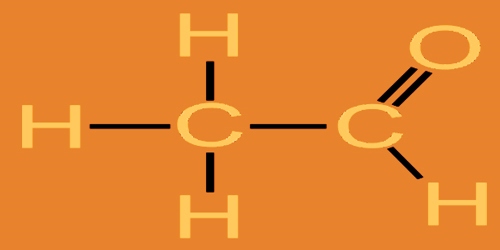

The study team’s formulations call for gelatinizing and plasticizing the starch in the presence of plasticizers, typically water and a different plasticizer with a higher boiling point.

It is highly likely that plasticized starch, which is surrounded by plasticizer molecules, will retrograde, or partially regain its original ordered structure, which will result in a loss of characteristics.

The method the researchers came up with, however, essentially prevents this migration, increasing the useful life of these materials without compromising their mechanical qualities, biodegradability, compostability, or water solubility.