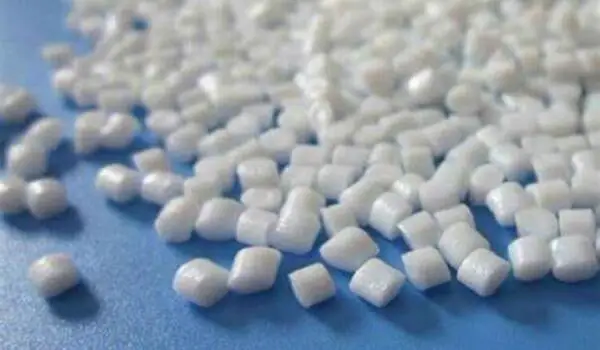

Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P) is the most common thermoplastic polymer resin of the polyester family and is used in clothing fibers, liquid, and food containers, thermoforming for manufacturing, and engineering resins in combination with glass fiber. Because of its great combination of qualities, it is a form of plastic polymer that is widely employed in a variety of applications.

The annual production of PET in 2016 was 56 million tons. The largest application (almost 60%) is in fibers, with bottle manufacture accounting for around 30% of global demand. PET is commonly referred to as polyester in the context of textile applications, whereas the abbreviation PET is commonly used in the context of packaging.

Polyester makes up about 18% of world polymer production and is the fourth-most-produced polymer after polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC).

Here are some key characteristics and uses of PET:

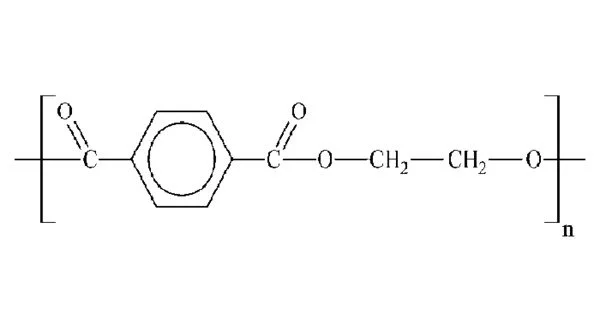

- Chemical Structure: PET is a synthetic polymer made from repeating units of ethylene glycol and terephthalic acid. Its chemical formula is (C10H8O4)n, and it falls into the polyester family of polymers.

- Transparency and Clarity: PET is known for its clarity and transparency, making it an ideal material for packaging products where visibility of the contents is important. It is commonly used for clear plastic bottles for beverages and other liquid products.

- Strength and Durability: PET is a strong and durable material, making it suitable for applications where the packaging needs to withstand mechanical stress, such as carbonated beverage bottles.

- Lightweight: PET is relatively lightweight, which makes it a popular choice for single-use beverage containers as it reduces shipping costs and environmental impact.

Recyclability

PET is a highly recyclable material. It is one of the most recycled plastics in the world, and recycled PET (rPET) is widely employed in the manufacture of a variety of products, including new PET bottles, clothes, and fiberfill for pillows and jackets.

PET has a high heat resistance, which is crucial for applications involving hot liquids or food. PET is resistant to many common chemicals, making it suitable for a wide range of uses, including cleaning products and medicinal containers.

Applications

PET can be converted into fibers for use in textiles. It is commonly referred to as polyester when used in textiles, and it is used to produce apparel, furniture, and a variety of other fabric goods. It is a good electrical insulator and is used to make electrical components and insulating materials.

PET is also used to create transparent films and sheets that are utilized in packaging, graphics, and laminates. It is often used for food packaging, such as containers for beverages, sauces, condiments, and pre-packaged items. Regulatory agencies have cleared it for direct contact with food.

Because of its biocompatibility and chemical resistance, PET is utilized in the medical profession for things such as PET bottles for medications, medical fabrics, and some medical gadgets.