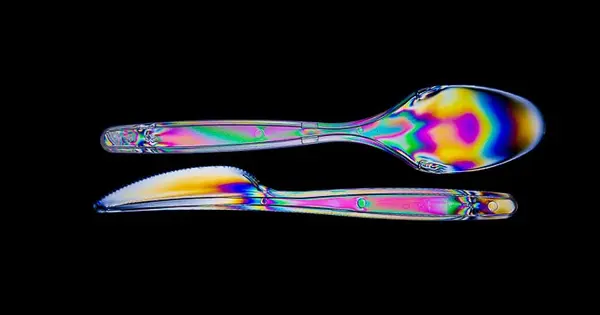

Photoelasticity is a technique used to visualize and measure the stress distribution in a transparent material by observing the changes in its optical properties. When a transparent material is subjected to stress, it experiences changes in its refractive index, which can be visualized using polarized light.

Photoelasticity describes changes in a material’s optical properties as a result of mechanical deformation. It is a property of all dielectric media and is frequently used to experimentally determine the stress distribution in a material, where it provides a picture of stress distributions around material discontinuities. Photoelastic experiments (also known as photoelasticity) are useful for determining critical stress points in a material and determining stress concentration in irregular geometries.

The technique involves placing a model made of a transparent, photoelastic material between two polarizing filters. When stress is applied to the model, the polarized light passing through the material becomes distorted due to the changes in the refractive index caused by the stress. This produces a pattern of bright and dark regions, known as fringes, which correspond to the stress distribution in the material.

By analyzing the fringe patterns, engineers and researchers can determine the magnitude and direction of stresses in the material. Photoelasticity is commonly used in engineering applications, such as in the design of structural components, and in materials science to study the behavior of materials under stress.

Advantages & Disadvantages of Photoelasticity

The main advantages of photoelasticity are its ease of use and the fact that it can be used in both static and dynamic investigations. Photoelasticity, as opposed to analytical methods of stress determination, provides a more accurate determination of stress distribution, even in irregular materials. It returns consistent full-field values of the difference between the main stresses in a model’s plane. Photoelasticity also provides a non-vanishing main stress value along the model’s perimeters, where stress levels can be the highest. Basic investigations require only a small investment in equipment and materials.

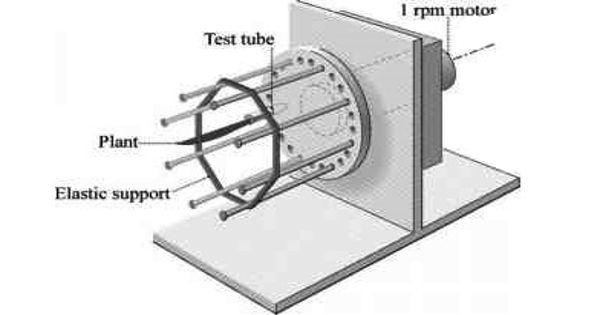

However, there are some drawbacks to this method. Unless photoelastic coatings are used, photoelasticity necessitates the creation of a model of the actual part. Furthermore, the calculations necessary to separate the principal stress values at a general interior point are extremely complex. Expensive equipment is required for precise stress analysis in large components. Furthermore, 3D photoelasticity experiments are time-consuming and labor-intensive.

Applications

Recent advances in photoelastic analysis allow for real-time stress monitoring of structures. Quick cure coatings, fully automated polariscope systems, and high-speed CCD cameras that can monitor changing stress patterns in real time have replaced time-consuming coating applications and manual reading of fringes. The modern photoelastic technique provides a powerful and unique method for full-field dynamic stress analysis.