Thermoelectric devices are made of materials that can convert a temperature difference into electricity without the use of moving parts, making thermoelectrics a potentially appealing source of electricity. The phenomenon is reversible: applying electricity to a thermoelectric device can result in a temperature difference.

The addition of sensors and improved communication tools has made providing lightweight, portable power even more difficult. Army-funded research demonstrated a novel method for converting thermal energy into electricity, which could provide Soldiers with compact and efficient power on future battlefields.

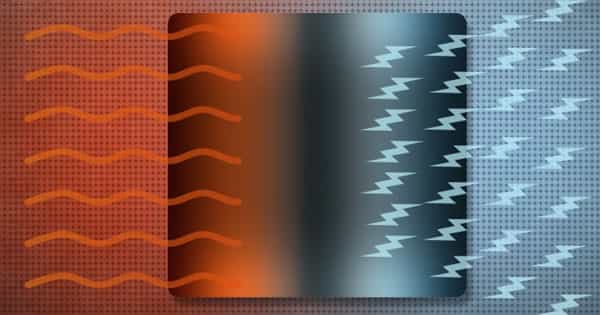

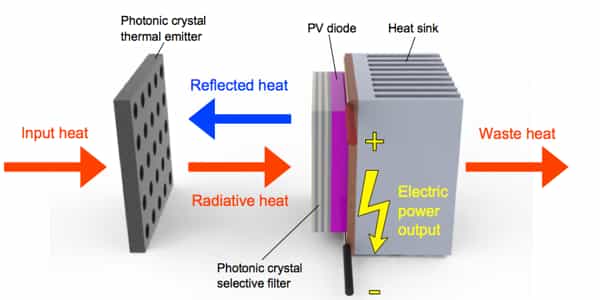

Hot objects emit photons, which are particles of light, into their surroundings. A photovoltaic cell can capture the emitted photons and convert them to use electric energy. This approach to energy conversion is known as far-field thermophotovoltaics, or FF-TPVs, and has been in development for many years; however, it has a low power density and thus requires high emitter operating temperatures.

The study, conducted at the University of Michigan and published in Nature Communications, demonstrates a novel approach in which the distance between the emitter and the photovoltaic cell is reduced to the nanoscale, allowing for much higher power output than is possible with FF-TPVs at the same emitter temperature.

With the addition of sensors and enhanced communication tools, providing lightweight, portable power has become even more challenging. New research demonstrated a new approach to turning thermal energy into electricity that could provide compact and efficient power.

Near-field thermophotovoltaics, or NF-TPV, is an approach that captures energy that would otherwise be trapped in the near field of the emitter. It employs custom-built photovoltaic cells and emitter designs that are ideal for near-field operating conditions.

According to Dr. Edgar Meyhofer, professor of mechanical engineering at the University of Michigan, this technique demonstrated a power density nearly an order of magnitude higher than that of the best-reported near-field-TPV systems, while also operating at a six-fold higher efficiency, paving the way for future near-field-TPV applications.

Scientists have discovered that some topological materials can be converted into efficient thermoelectric devices via nanostructuring, a technique used by scientists to create a material by patterning its features at the nanometer scale. Scientists believe that the thermoelectric advantage of topological materials stems from reduced thermal conductivity in their nanostructures. However, it is unclear how this increase in efficiency relates to the material’s inherent, topological properties.

“The Army uses large amounts of power during deployments and battlefield operations, which must be carried by the Soldier or a weight-constrained system,” said Dr. Mike Waits, Army Research Laboratory, U.S. Army Combat Capabilities Development Command. “If successful, near-field-TPVs could serve as more compact and efficient power sources for Soldiers in the future, as these devices can operate at lower operating temperatures than conventional TPVs.”

The efficiency of a TPV device is defined as the proportion of total energy transfer between the emitter and the photovoltaic cell that is used to excite the electron-hole pairs in the photovoltaic cell. While increasing the temperature of the emitter increases the number of photons above the cell’s band-gap, the number of photons below the band-gap that can heat up the photovoltaic cell must be minimized.

“This was accomplished by fabricating thin-film TPV cells with ultra-flat surfaces and a metal back reflector,” said Dr. Stephen Forrest, University of Michigan professor of electrical and computer engineering. “Photons above the cell’s bandgap are efficiently absorbed in the micron-thick semiconductor, while photons below the bandgap are reflected back to the silicon emitter and recycled.”

The researchers grew thin-film indium gallium arsenide photovoltaic cells on thick semiconductor substrates before peeling away the cell’s very thin semiconductor active region and transferring it to a silicon substrate. All of these advancements in device design and experimental methodology resulted in a novel near-field TPV system.

“The team has achieved a record 5 kW/m2 power output, which is an order of magnitude greater than systems previously reported in the literature,” said Dr. Pramod Reddy, a mechanical engineering professor at the University of Michigan.

The researchers also used cutting-edge theoretical calculations to estimate the performance of the photovoltaic cell at each temperature and gap size, and they found that the experiments and computational predictions agreed well.

“This current demonstration meets theoretical predictions of radiative heat transfer at the nanoscale, and directly demonstrates the potential for developing future near-field TPV devices for Army applications in power and energy, communication, and sensors,” said Dr. Pani Varanasi, program manager at DEVCOM ARL, which funded this work.