Ag nanowires are one-dimensional structures composed of silver atoms that have a diameter of a few nanometers (typically less than 100 nm) and a length of several micrometers. These structures have unique optical, electronic, and mechanical properties that make them attractive for a wide range of applications in fields such as electronics, photonics, and biomedicine.

Nano-joints in the AgNWs Interconnect Network exhibit atomic flow behavior, according to Xi’an Jiaotong University researchers. The heat welding procedure and the atomic evolution behavior of Ag nanowires were investigated in order to further enhance the joint quality using a mix of in situ experiments and molecular dynamics simulations.

The group does a methodical analysis of the atomic flow behavior during the production of several Ag nanowire junctions. Systematically investigating the effects of processing time, temperature, and stress distribution due to spatial organization on nanojoints.

Also, the atomic interface behavior of the nanojoints and their failure mechanisms were studied. These findings might help flexible electronics and transparent conductive materials utilize Ag nanowire connectivity networks in industrial settings.

Many techniques, including chemical vapor deposition, electrochemical deposition, and template-assisted synthesis, can be used to create Ag nanowires. By modifying Ag nanowires’ size, shape, and crystal structure, one may specifically control their attributes.

The research of the temperature dependency of joints and thermal defect damage mechanisms during their welding process becomes more crucial as the size of nano-joints moves to the nanoscale because of their increased thermal sensitivity.

How to effectively improve the welding quality of AgNWs joints and ensure the application stability of the joints has always been the focus of research. With the further integration and miniaturization of devices, the thermal sensitivity and thermal damage mechanisms of nano-joints in the application process will also attract more and more attention in the future.

Professor Xuesong Mei

When welding Ag nanowires, the capillary phenomenon is more evident in the nano-gaps, and the weld shape is affected by local stress in addition to temperature.

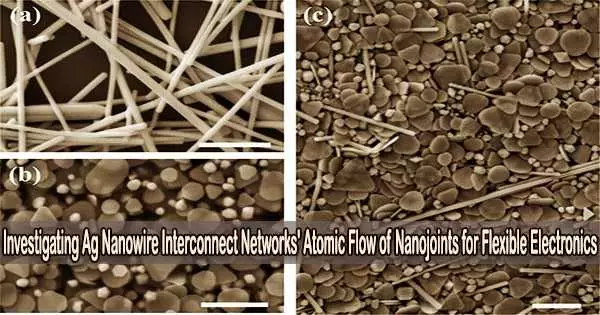

The initial spacing and alignment direction between the nanowires affect the joint’s final quality in thermally induced welding techniques. Three types of nano-joints can be obtained during the welding process: head-to-head, head-to-side (T-shaped) and side-to-side (X-shaped) joints.

The weld morphology for the first two joint shapes is primarily controlled by temperature and horizontal pitch. The top-and-bottom spatial structures of X-shaped nano-joints cause local pressures to have a significant impact on the joint shape in addition to temperature.

One of the lead researchers, Professor Jianlei Cui, commented, “The characteristics of the joint in the interconnected network of AgNWs are not only influenced by the temperature, but also by the local stress and its interaction with the substrate, at the same time capillary interactions show a non-negligible influence in interfacial flow at the nanoscale. Furthermore, within the right temperature range, the atomic flow of the joint becomes more and more adequate with increasing treatment time and the quality of the joint becomes better and better.”

We are able to directly witness and examine the development of the atomic morphological features during the welding of Ag nanowires thanks to the in-situ heating system of the electron microscope.

The author Xiaoying Ren explained, “In our work, we directly observed the excitation and resorption of a large number of Ag nanoparticles on the surface of AgNWs during thermal excitation, and the mechanism of nanoparticle formation may be due to capillary-induced surface diffusion and permeation.”

The gradual filling of the nanogaps with Ag atoms that occurs together with the stimulation and reabsorption of these nanoparticles results in the gradual formation of fully welded nano-joints over time.

The authors discovered that AgNWs produce specific stress concentrations in the curved parts, and that these parts typically exhibit localized damage or fracture under thermal excitation in the subsequent process. This led them to further investigate the impact of local stress on X-shaped nano-junctions.

During the formation of an X-joint, the upper nanowires will flow violently under the influence of local stress and temperature, and their atoms will flow along the surface of the lower nanowires, eventually forming an encapsulated nano-joint, which leads to the formation of a large number of defects on both sides of the upper nanowire joint, and these X-shaped nano-junctions are the first to fracture on both sides of the upper nanowires during the later thermal excitation process.

In order to further analyze the evolution of the atomic behavior of Ag nanowires under thermal excitation and the mechanism of thermal damage, the author Chenchen Huang said that “We have systematically analyzed the Rayleigh destabilization of Ag nanowires under thermal excitation using molecular dynamics simulations, and the results show that Ag nanowires form equally spaced nanoparticles due to Rayleigh destabilization at high temperatures.”

Professor Xuesong Mei said, “How to effectively improve the welding quality of AgNWs joints and ensure the application stability of the joints has always been the focus of research. With the further integration and miniaturization of devices, the thermal sensitivity and thermal damage mechanisms of nano-joints in the application process will also attract more and more attention in the future.”