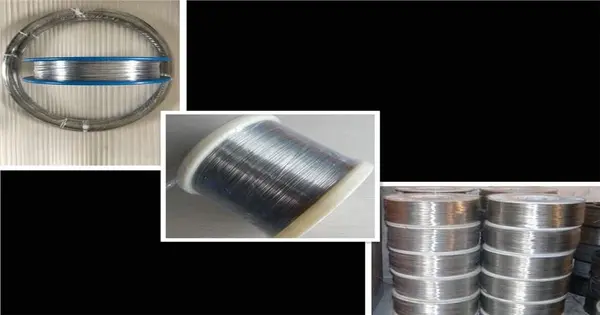

Nickel titanium, often known as nitinol, is a metal alloy composed of nickel and titanium in about equal atomic percentages. It is a one-of-a-kind and adaptable alloy with shape memory and superelastic characteristics. The weight % of nickel is used to identify alloys, such as nitinol 55 and nitinol 60. It is made up of roughly equal parts nickel and titanium, giving rise to the term “Nitinol” (Ni for nickel, Ti for titanium, and “NOL” for Naval Ordnance Laboratory, where it was discovered).

Nitinol alloys have two distinct and related properties: shape memory and superelasticity (also known as pseudoelasticity). Shape memory refers to nitinol’s capacity to deform at one temperature, remain deformed when the external force is withdrawn, and then return to its original, undeformed shape when heated over its “transformation temperature.”

The ability of a metal to undergo massive deformations and instantly return to its original shape after an external load is removed is referred to as superelasticity. Nitinol can deform and recover to its original shape 10-30 times faster than regular metals. The shape memory effect or superelasticity of nitinol is dependent on whether it is above the transition temperature of the specific alloy.

Here are some key properties and uses of nickel-titanium (Nitinol):

- Shape Memory Effect: One of Nitinol’s most notable properties is its shape memory effect. This means it can “remember” a certain shape and return to it when heated after being deformed. For example, you can bend a Nitinol wire into a new shape, and it will restore to its original shape when heated.

- Superelasticity: Nitinol is also superelastic, meaning it can be deformed significantly and still return to its original shape when the deforming force is removed. Because of its features, it can be used in a variety of applications, including medical equipment and eyeglass frames.

- Biocompatibility: Nickel titanium is biocompatible, making it suitable for use in medical implants and devices. It is often used in stents, guidewires, and other medical applications because it can be inserted in a deformed state and then return to its intended shape inside the body.

- Temperature Dependence: The shape memory effect in Nitinol is temperature-dependent. It typically undergoes a reversible phase transformation at a specific temperature, known as the “transformation temperature” or “transition temperature.” Heating the material above this temperature causes it to return to its remembered shape while cooling it below this temperature allows it to be deformed.

Applications

Beyond the medical field, nickel-titanium has a wide range of applications. It’s employed in eyeglass frames, robots, actuators, orthodontic braces, and a variety of aeronautical and industrial applications where its unique qualities can be beneficial.

Nitinol’s unique qualities can be modified by varying its composition, including the nickel-to-titanium ratio and the inclusion of trace amounts of other elements. The transition temperature and mechanical characteristics can vary depending on the composition.

Because of its shape memory and superelastic qualities, working with Nitinol can be difficult. Machining, shaping, and heat treatment frequently necessitate the use of specialized techniques and equipment.

Nitinol’s unique combination of properties has made it a valuable material in various industries, particularly in medical and engineering applications where its ability to recover its original shape is crucial.