Chemical recycling technologies can degrade plastics into their constituent parts and convert them into valuable secondary raw materials. These materials can then be recycled to make new chemicals and plastics. Plastic waste streams can be converted back into feedstock for the chemical industry and allocated to products manufactured in BASF’s integrated chemical production network (Verbund) using a mass balance approach with chemical recycling.

Cornell University’s new research aims to simplify the process of chemical recycling, an emerging industry that could convert waste products back into natural resources by physically breaking down plastic into the smaller molecules from which it was originally produced.

In a new paper, “Consequential Life Cycle Assessment and Optimization of High-Density Polyethylene Plastic Waste Chemical Recycling,” published in the journal ACS Sustainable Chemistry & Engineering, Fengqi You, the Roxanne E., and Michael J. Zak Professor in Energy Systems Engineering and doctoral student Xiang Zhao detail a framework incorporating several mathematical models and methodologies that factor everything from chemical recycling equipment, processes, and energy sources, to environmental effects and the market for end products.

New research aims to ease the process of chemical recycling — an emerging industry that could turn waste products back into natural resources by physically breaking plastic down into the smaller molecules it was originally produced from.

The framework is the first of its kind to quantify the environmental impacts of plastic waste chemical recycling throughout its life cycle, including climate change and human toxicity.

Since the 1950s, billions of tons of plastic have been produced, but only 91 percent of it has been recycled, according to one widely cited study. While there are concerns about growing landfills and contaminated natural areas, some see the failure to reduce and reuse plastic as a missed economic opportunity.

That is why the emerging industry of chemical recycling is attracting the attention of the waste industry as well as researchers like You, who are assisting in the identification of optimal chemical recycling technologies and providing a roadmap for the industry’s future.

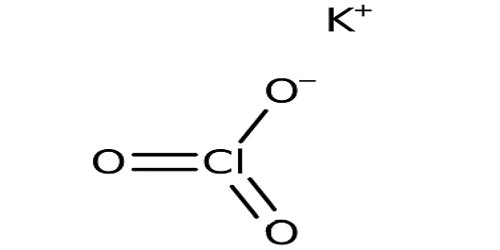

Chemical recycling not only creates a ‘circular economy,’ in which a waste product can be recycled into a natural resource, but it also makes it easier to recycle plastics like high-density polyethylene, which is used to make rigid bottles, toys, underground pipes, and mail package envelopes.

You’s framework can quantify the environmental consequences of market dynamics that are often overlooked in traditional life-cycle sustainability assessments. It’s also the first to combine life-cycle analysis, market information, and economic equilibrium with superstructure optimization, a computational technique for searching over a large combinatorial space of technology pathways for cost minimization.

When compared to more traditional analytical tools, the paper emphasizes the advantages of consequential life-cycle optimization. When compared to the attributional life-cycle assessment approach typically used in environmental assessment studies, life-cycle optimization produced a more than 14 percent reduction in greenhouse gas emissions and a more than 60 percent reduction in photochemical air pollution in one scenario to maximize economic outcomes while minimizing environmental impacts.

While the study provides industry experts and policymakers with a general roadmap for advancing chemical recycling and a circular economy for plastics, there are numerous options and variables to consider along the technological path. For example, if market demand for basic chemicals such as ethylene and propylene is high enough, the framework recommends one type of chemical separation technology, whereas if butane or isobutene is desired, another type of technology is best.

You said, “It’s a chemical process with so many possibilities.” “What technology would we use if we wanted to invest in chemical recycling? That is highly dependent on the composition of our waste, polyethylene plastic variants, and current market prices for end products such as fuels and hydrocarbons.”

Chemical recycling’s environmental consequences are influenced by factors such as chemical feedstock and product supplier processes. For example, the framework discovered that producing butene on-site rather than having it delivered can reduce photochemical air pollution from recycling plants by nearly 20%, while onsite use of natural gas increases potentially harmful ionizing radiation by more than 37%.

“The tricky part is that there’s always something we can twist and adjust in the technology and process,” You said, adding that as new chemical recycling techniques emerge and markets shift, consequential life-cycle optimization will remain a powerful tool for guiding the emerging industry. The National Science Foundation helped fund some of the research.