Polyvinylidene fluoride (PVDF) is a thermoplastic fluoropolymer material that is widely used in various applications due to its excellent chemical resistance, high melting point, and exceptional mechanical properties. It is a semi-crystalline polymer with a high degree of molecular alignment and has a high level of resistance to UV radiation, high temperatures, and many chemicals.

PVDF is a thermoplastic fluoropolymer made from the polymerization of vinylidene difluoride. It has the chemical formula (C2H2F2)n. PVDF is a specialty plastic that is used in applications that require high purity as well as resistance to solvents, acids, and hydrocarbons. In comparison to other fluoropolymers, such as polytetrafluoroethylene, PVDF has a low density of 1.78 g/cm3.

It comes in piping products, sheet, tubing, films, plate, and an insulator for premium wire. It is commonly used in the chemical, semiconductor, medical, and defense industries, as well as lithium-ion batteries, and can be injected, molded, or welded. It’s also available as a cross-linked closed-cell foam, which is increasingly being used in aviation and aerospace applications, as well as an exotic 3D printer filament. Because it is FDA-compliant and non-toxic below its degradation temperature, it can also be used in repeated contact with food products.

Application

PVDF is commonly used in the manufacture of pipes, fittings, and valves for the chemical industry, as well as in the production of wire and cable insulation, lithium-ion batteries, and solar panels. It is also used in the production of membranes for water treatment and gas separation, and as a coating material for architectural and industrial applications.

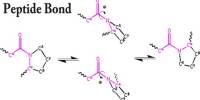

One of the unique properties of PVDF is its piezoelectricity, which means it can generate an electric charge in response to mechanical stress or pressure. This property makes PVDF an ideal material for sensors and transducers used in medical, automotive, and aerospace applications.

Common industry applications for PVDF thermoplastics include:[8]

- chemical processing,

- electricity, batteries and electronic components,

- construction and architecture,

- healthcare and pharmaceutics,

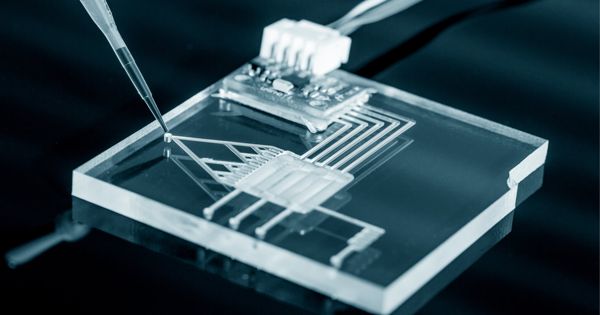

- biomedical research,

- ultra-pure applications,

- nuclear waste handling,

- petrochemical, oil and gas,

- food, beverage processing,

- water, wastewater management.

PVDF is known for its excellent resistance to UV radiation, weathering, and corrosion, which makes it ideal for outdoor applications. It is also a good electrical insulator and has excellent fire resistance properties. Overall, PVDF is a highly versatile material that can be used in a wide range of applications, from electrical and electronics to chemical processing and construction.