Nanolamination is the production of materials that are fully dense, ultra-fine grained solids that exhibit a high concentration of interface defects. The properties of fabricated nanolaminates depend on their compositions and thicknesses. Nanolaminate composite materials are a category of two-dimensional nanomaterials in the fields of chemistry, materials science, and condensed matter physics.

Production

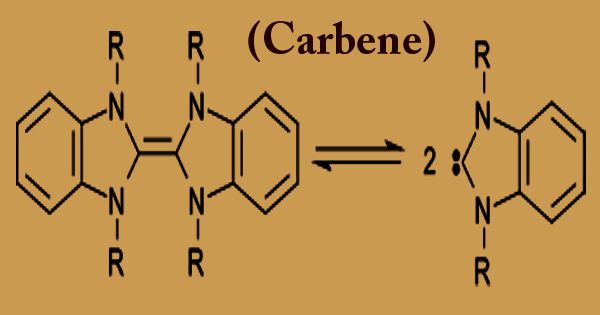

Nanolaminates can be formed with multiple alternating interface layers and high-k layers, where intermediate interface layers can break up the crystal structure of the high-k materials and lower leakage levels. It can be grown using atom-by-atom deposition techniques that are designed with different stacking sequences and layer thicknesses. Nanolaminates can typically be developed using bottom-up techniques that are designed with various stacking series along with layer thicknesses.

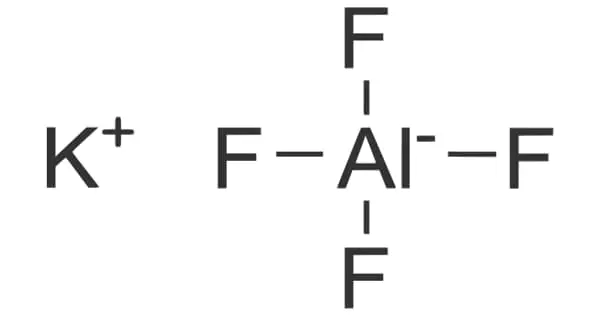

Electrolytic reduction

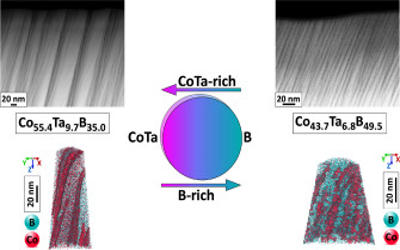

Electrolytic reduction allows the production of metals and metal alloys in sub-µm-thick layers. It can be employed to create alloys with properties such as improved toughness, strength, thermal properties, and corrosion that are a function of the interfaces in the nanolayers. The properties can be established during the fabrication process by size control of each coating layer and interfacial chemical reactions between layers. They can be created using a bath containing multiple metal ion elements. By changing the current at precise moments to select a different element, it can create a layered structure. Coatings of up to a centimeter thick have been created. The influence of the interface layer in the nanolaminate composite materials is considered from the viewpoint of conferring high-performance characteristics. By controlling material interfaces at the nano-scale, Modumetal Inc. has developed a method for creating a new class of alloys with precisely defined properties through nanolamination.

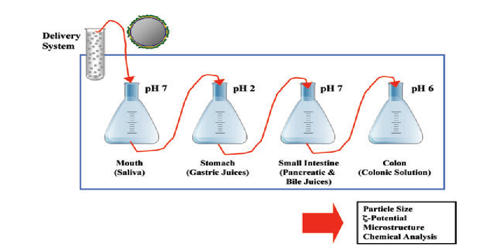

Fig: Nanolamination Electrolytic reduction

Applications

The application includes those that take advantage of enhanced mechanical properties or for devices such as energy storage and memory storage capacitors. By deploying nano laminated materials as cladding on conventional alloys, the cost of corrosion and wear protection is significantly decreased.

- Oil and gas

Corrosion-resistant, structural tubular, and casings are important infrastructure assets in the oil and gas industry. Tubulars and casings are subject to aggressive good conditions, serving to permit operations across extreme formation and production pressure differentials, in high temperatures and in highly corrosive environments that contain hydrogen sulfide (H

2S), carbon dioxide (CO2), and chlorides.

- Electronics

Nanolaminate dielectrics can have efficient dielectric constant and high insulation characteristics. Dielectric materials with giant dielectric constants can be fabricated as modified single, binary, and perovskite oxides.