Thermoplastic Polyurethane (TPU) is a type of polyurethane plastic that has numerous qualities such as flexibility, transparency, and resistance to oil, grease, and abrasion. It is a versatile and frequently used polymer material that is well known for its great combination of physical qualities and processing benefits. They are technically thermoplastic elastomers made up of linear segmented block copolymers with hard and soft segments. It is a thermoplastic elastomer, which combines the qualities of thermoplastics and elastomers (rubbers).

Chemistry

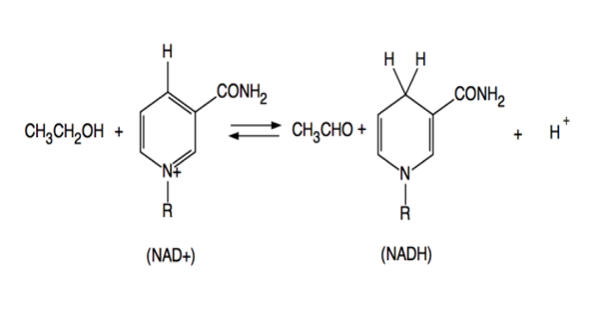

TPU is a block copolymer composed of alternating sequences of hard and soft segments or domains generated by the reaction of (1) diisocyanates with short-chain diols (so-called chain extenders) and (2) diisocyanates with long-chain diols. A wide range of TPU can be created by altering the ratio, structure, and/or molecular weight of the reaction molecules. This allows urethane scientists to fine-tune the polymer’s structure to the desired final qualities of the material.

Here are some key characteristics of TPU:

- Flexibility and Elasticity: TPU is known for its flexibility and elasticity, making it perfect for applications that require both durability and flexibility. It can be easily stretched and bent without being permanently deformed.

- High Abrasion Resistance: TPU offers exceptional abrasion resistance, making it ideal for applications involving friction and wear, such as conveyor belts, gaskets, and seals.

- Chemical Resistance: TPU is chemical, oil, and solvent resistant, making it suited for usage in severe situations.

- Wide Range of Hardness: TPUs come in a variety of hardness levels, ranging from very soft and flexible to hard and unyielding, depending on the formulation. This adaptability enables a wide range of applications in a variety of industries.

- Ease of Processing: TPUs can be processed using conventional thermoplastic processing methods such as injection molding, extrusion, and blow molding, which makes them easy to manufacture into a wide range of products.

Applications: TPU is used in a wide variety of applications, including but not limited to:

- Footwear, including shoe soles and sportswear

- Automotive parts, such as seals and gaskets

- Consumer electronics, including protective cases

- Medical devices and tubing

- Industrial belts and hoses

- Flexible tubing and hoses

- Films and sheets for packaging and membranes

- 3D printing filament

TPU’s specific qualities might vary according on the formulation, which can be adjusted to fit the needs of a certain application. TPU’s versatility in material qualities, paired with its simplicity of processing, has resulted to its broad application in a variety of industries.