Colossal Carbon Tubes

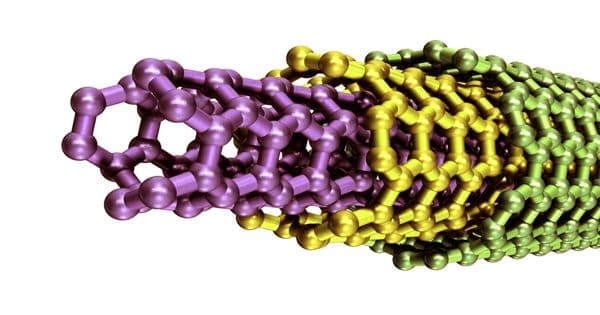

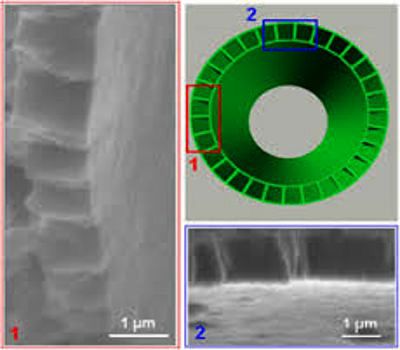

Carbon nanotubes (CNTs) are famed for being a future wonder material that will enable a swathe of super-strong but light applications from racing bikes to computer components. Colossal carbon tubes (CCTs) are a tubular form of carbon. In contrast to the carbon nanotubes (CNTs), colossal carbon tubes have much larger diameters ranging between 40 and 100 μm. Compared with carbon nanotubes, colossal carbon tubes have a much bigger size, with a diameter of between 40 and 100 mum and a length in the range of centimeters. Their walls have a corrugated structure with abundant pores, as in corrugated fiberboard, where the solid membranes have a graphite-like layered structure. Significantly, the walls of the colossal tubes are composed of macroscopic rectangular columnar pores and exhibit an ultralow density comparable to that of carbon nanofoams.

A colossal carbon tube is a tubular form of carbon. Their diameter is much – tens of thousands of times more carbon nanotubes. They have a structure resembling corrugated cardboard, so are flexible and elastic, perfectly stretched, and at the same time retain their high strength.

Colossal carbon tubes have a wall consisting of several layers of atoms of carbon. The distance between the carbon layers as in graphite is 0.34 nm. CCTs have technologically attractive properties such as ultra light-weight, extremely high strength, excellent ductility, and high conductivity – which make them possibly suitable for clothing. On the outer surface of the tubes is a layer of amorphous carbon and the inner layer is missing. The wall thickness is about 1.5 microns. They are excellent (105 siemens per meter) electrical conductors, are 15 times stronger than the strongest carbon fiber (T1000), have 30 times the tenacity of Kevlar, and are 224 times stronger than individual cotton fibers. The tube walls are not solid. The tubes exhibit an ultra-low density comparable to that of carbon nanofoams. They have a corrugated structure with a large number of pores of rectangular cross-section, similar to the corrugated carton. Pores separated by carbon layers with a thickness of about 100 nm.

Porous forms of carbon have been made before, but not in this fibrous form. CCTs have a tensile strength of 7 GPa, and high specific strength (tensile strength per density), and a breaking length of 6,000 km. Due to the unique structure of the colossal carbon tube to be flexible and elastic, perfectly stretched and at the same time are very durable material, stronger than carbon nanotubes. This exceeds the specific strength of the strongest carbon nanotube; this strength is sufficient to support a space elevator if retained in a fabricated macroscale structure. Under load the tube does not break and gradually stretched in length, decreasing in diameter.

CCTs conduct electricity and show some of the properties of semiconductors. The scientists said that the created CCTs have a unique architecture with rectangular macropores across the tube walls and layered crystal structures in the solid walls.