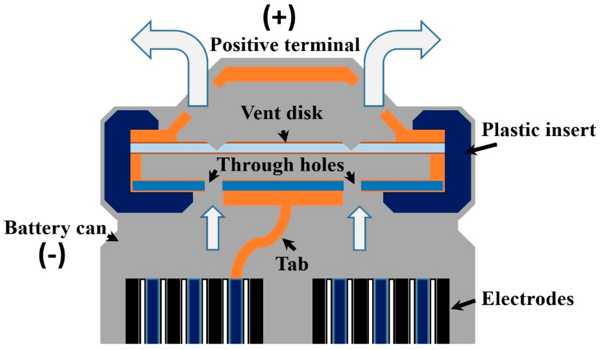

With increased interest in backup power, solar power storage, and electric vehicles, the race to improve rechargeable lithium battery performance is on. A Berkeley Lab team has developed a simple, quick, and low-cost method for measuring battery performance.

The new technique, developed by Ravi Prasher and Sean Lubner of the Energy Technologies Area, uses thermal waves to measure local lithium concentration as a function of depth inside battery electrodes. The new method employs thermal waves to determine the local concentration of lithium as a function of the depth of the battery electrodes within. Their findings were published in the journal Joule recently.

“With our technique, you take a battery and place the sensor on top of it,” Prasher explained. “The sensor sends a signal, and depending on the frequency of the signal, you can control how deep the wave penetrates. You can control the depth of penetration this way. It is much less expensive and faster than other diagnostic procedures, and it provides a low-cost and quick way to measure battery characteristics.”

A Berkeley Lab team has developed an easy, fast, and inexpensive method to measure battery performance. The new method uses thermal waves to measure the local concentration of lithium as a function to measure the depth of battery electrodes inside.

The method involves taking a battery and placing a sensor on top of it. The sensor sends a signal to this apparatus, and the depth of penetration of the wave can be changed depending on the signal frequency. The method is also much faster and less expensive than other diagnostic procedures. This allows for a more efficient and cost-effective method of measuring battery characteristics.

This method is known as a “operando” technique because it works while the reaction is taking place, demonstrating that thermal wave sensing provides spatial information of lithium concentration comparable to experimental results obtained using synchrotron X-ray diffraction but without the need for a large synchrotron facility such as the Advanced Light Source.

Measuring battery performance is difficult, making testing new materials to improve battery performance time-consuming and costly. Different portions of electrodes have different local states of charge and age at varying rates when testing materials to improve charging speed, so spatially averaged chemical information provided by existing battery diagnostic tools is insufficient for understanding lithium-ion battery degradation.

According to Prasher, the team is currently testing the procedure at the lab scale, and the next step will be to test commercial batteries.

“This work demonstrates the power of interdisciplinary science,” Lubner said. “The project combines techniques and knowledge from the thermal and electrochemistry communities to achieve a capability that would not have been possible otherwise.”

“With our technique, you take a battery and place the sensor on top of the battery,” said Ravi Prasher, who led the study. The sensor sends a signal and depending on the frequency of the signal, you can control how deep the wave penetrates. You can control the depth of penetration this way. It is much less expensive and faster than other diagnostic procedures, and it provides a low-cost and quick way to measure battery characteristics.”

“This work demonstrates the strength of interdisciplinary science,” said Sean Lubner of the Energy Technologies Area. The project combines techniques and knowledge from the thermal and electrochemistry communities to achieve a capability that would not have been possible otherwise.”