Captured CO2 can be converted into carbon-neutral fuels, but technological progress is required. A new catalyst increases the production of long-chain hydrocarbons in chemical reactions by 1,000 times over existing methods, according to new research. Researchers have devised an efficient method for converting carbon dioxide into clean, sustainable fuels that produce no unwanted byproducts or waste.

Researchers from the University of Cambridge have previously demonstrated that biological catalysts, or enzymes, can produce fuels cleanly and efficiently using renewable energy sources. Their most recent study increased fuel production efficiency by 18 times in a laboratory setting, demonstrating that polluting carbon emissions can be efficiently converted into green fuels with no wasted energy. The findings are detailed in two papers published in Nature Chemistry and Proceedings of the National Academy of Sciences.

Most methods for converting CO2 into fuel generate undesirable byproducts such as hydrogen. Scientists can change the chemical conditions to reduce hydrogen production, but this also reduces CO2 conversion performance: cleaner fuel can be produced, but at the expense of efficiency.

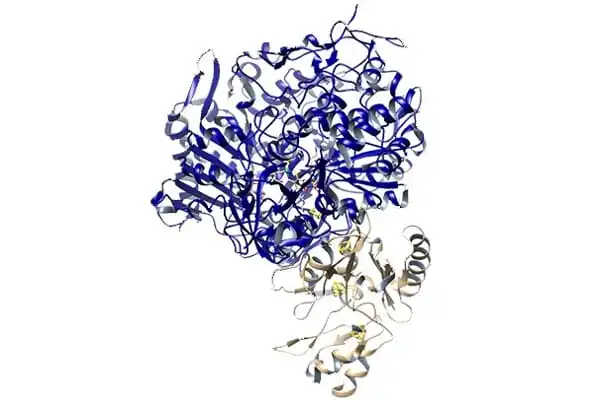

The proof of concept developed by Cambridge relies on enzymes isolated from bacteria to power the chemical reactions that convert CO2 into fuel, a process known as electrolysis. Although enzymes are more efficient than other catalysts such as gold, they are extremely sensitive to their local chemical environment. If the local environment isn’t just right, the enzymes break down and the chemical reactions slow down.

Many of the problems with CO2 electrolysis simply disappear once better catalysts are developed. We’re demonstrating to the scientific community that once we can produce future catalysts, we’ll be able to eliminate many of the current compromises, because what we learn from enzymes can be transferred to synthetic catalysts.

Dr. Esther Edwardes Moore

The Cambridge researchers developed a method to improve the efficiency of electrolysis by fine-tuning the solution conditions to alter the local environment of the enzymes, in collaboration with a team from the Universidade Nova de Lisboa in Portugal.

“Enzymes have evolved over millions of years to be extremely efficient and selective, and they’re great for fuel-production because there aren’t any unwanted by-products,” said Dr Esther Edwardes Moore, first author of the PNAS paper from Cambridge’s Yusuf Hamied Department of Chemistry. “However, enzyme sensitivity presents a unique set of challenges. Our method takes this sensitivity into account, adjusting the local environment to match the enzyme’s ideal working conditions.”

The researchers used computational methods to design a system to improve CO2 electrolysis. When compared to the current benchmark solution, the level of fuel production increased by 18 times when using the enzyme-based system.

To further improve the local environment, the researchers demonstrated how two enzymes can collaborate, one producing fuel and the other controlling the environment. They discovered that adding another enzyme sped up the reactions, increasing efficiency and reducing unwanted by-products.

“We ended up with exactly the fuel we wanted, with no byproducts and only marginal energy losses, producing clean fuels at maximum efficiency,” said Dr. Sam Cobb, the paper’s first author. “By drawing inspiration from biology, we will be able to develop better synthetic catalyst systems, which will be required if we are to deploy CO2 electrolysis on a large scale.”

“Electrolysis has a significant role to play in reducing carbon emissions,” said the study’s lead author, Professor Erwin Reisner. “Instead of capturing and storing CO2, which is extremely energy-intensive, we demonstrated a new concept for capturing carbon and producing something useful from it in an energy-efficient manner.”

The catalysts, according to the researchers, hold the key to more efficient CO2 electrolysis. Synthetic catalyst development has advanced significantly in recent years, but they still fall short of the enzymes used in this study.

“Many of the problems with CO2 electrolysis simply disappear once better catalysts are developed,” Cobb said. “We’re demonstrating to the scientific community that once we can produce future catalysts, we’ll be able to eliminate many of the current compromises, because what we learn from enzymes can be transferred to synthetic catalysts.”

“The improvement in performance was startling once we designed the concept,” Edwardes Moore said. “I was afraid we’d spend years trying to figure out what was going on at the molecular level, but once we realized how important the local environment was, it evolved really quickly.”

“In the future, we hope to apply what we’ve learned to tackle some difficult problems that current state-of-the-art catalysts struggle with, such as using CO2 straight from air, because these are conditions where the properties of enzymes as ideal catalysts can really shine,” Cobb said.