With the growing demand for flexible wearable electronics, researchers have looked into flexible energy storage devices such as flexible supercapacitors, which are lightweight, safe, and easy to integrate with other devices. Printing electronics has proven to be a cost-effective, simple, and scalable method of producing FSCs. Researchers examine printed FSCs in terms of their ability to create functional inks, design printable electrodes, and integrate functions with other electronic devices.

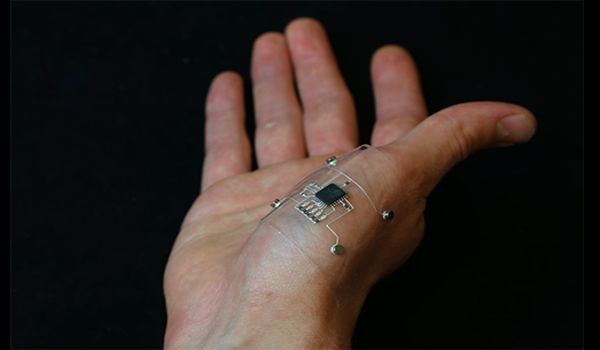

With the dramatic growth of smart devices that can exchange data with other devices over the internet using embedded sensors, software, and other technologies, demand for flexible wearable electronics has skyrocketed. As a result, researchers have focused on flexible energy storage devices, such as flexible supercapacitors (FSCs), which are lightweight, safe, and easy to integrate with other devices. FSCs have a high power density as well as quick charge and discharge rates.

Flexible supercapacitors are very appealing for a wide range of emerging portable lightweight consumer devices. The incorporation of a flexible electrode or substrate material to combine structural flexibility with the inherent high power density of supercapacitors is what distinguishes a flexible supercapacitor.

With the increase in demand for flexible wearable electronics, researchers have explored flexible energy storage devices, such as flexible supercapacitators, that are lightweight and safe and easily integrate with other devices.

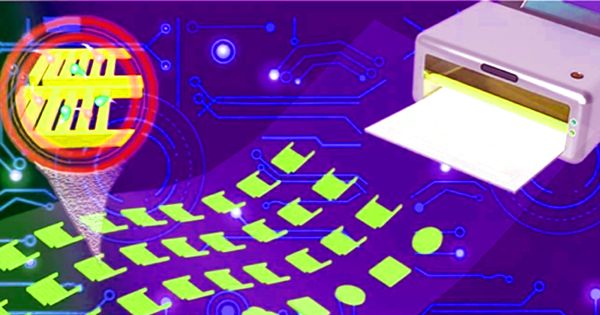

Printing electronics, or making electronics devices and systems using traditional printing techniques, has proven to be a cost-effective, simple, and scalable strategy for producing FSCs. Traditional micromanufacturing techniques can be costly and time-consuming.

Researchers from Wuhan University and Hunan University review printed FSCs in terms of their ability to formulate functional inks, design printable electrodes, and integrate functions with other electronic devices in AIP Publishing’s Applied Physics Reviews.

Flexible energy storage devices are critical to the development of next-generation wearable, compact, and portable electronics for medical, military, and civilian applications, such as flexible displays on phones, health monitoring devices, computers, and televisions. To that end, flexible supercapacitors are more appealing than batteries (LIBs) because they combine inherent high power density, fast charging/discharging capability, longer operation lifetime, and mechanical flexibility. Flexible supercapacitors can use either a non-Faradaic energy storage process like the electric double layer capacitor type or a Faradaic mechanism like the pseudocapacitors (PCs).

Printed FSCs are typically created by printing functional inks on flexible substrates using traditional organic and inorganic electrode materials. Because of the thin film structure, these printed devices can be bent, stretched, and twisted to a specific radius without compromising electrochemical function.

Furthermore, the supercapacitor’s rigid current collector components can be replaced with flexible printed parts. To fabricate the printed FSCs, various printing techniques such as screen printing, inkjet printing, and 3D printing have been well established.

“The development of miniaturized, flexible, and planar high-performance electrochemical energy storage devices is an urgent requirement to promote the rapid development of portable electronic devices in everyday life,” author Wu Wei stated. “In the future, we can imagine using any printer in our lives to print a supercapacitor to charge a mobile phone or smart wristband at any time.”

Two principles were discovered by the researchers for printable ink formulations. To begin, it is critical to include fewer ineffective additives, better conductive binders, and excellent dispersion electrode materials when selecting ink components. Second, the ink must have a suitable viscosity and a good rheology property to obtain excellent prints.

Printable functional materials, such as graphene and pseudocapacitive materials, are good core components of printed supercapacitators.

Supercapacitors, a unique class of energy storage devices, can outperform rechargeable batteries in terms of instant power delivery and the ability to withstand millions of charge-discharge cycles at higher current densities. Unlike batteries, which store energy through redox reactions, supercapacitors, specifically electrochemical double layer capacitors (EDLCs), store opposite charges at the interface of active layer/electrolyte only through physisorption, and their fast ion-exchange kinetics make them particularly appealing for use in high power applications such as hybrid electrical vehicles and power shunts.

Because printed electronics are flexible and inexpensive, they can be used to make solar cells, flexible OLED displays, transistors, RFID tags, and other integrated smart devices. This opens the door to a plethora of other applications, such as smart textiles, intelligent packaging, and smart labels.