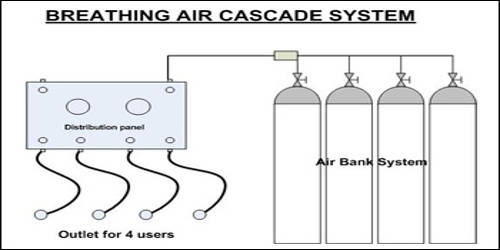

A cascade filling system is a high-pressure gas cylinder storage system that is used for the refilling of smaller compressed gas cylinders. In some applications, each of the large cylinders is filled by a compressor, otherwise, they may be filled remotely and replaced when the pressure is too low for effective transfer. The cascade system allows small cylinders to be filled without a compressor. In addition, a cascade system is useful as a reservoir to allow a low-capacity compressor to meet the demand of filling several small cylinders in close succession, with longer intermediate periods during which the storage cylinders can be recharged.

Uses

Breathing sets

A breathing set cylinder may be filled to its working pressure by decanting from larger (often 50 liters) cylinders. (To make this easy the neck of the cylinder of the Siebe Gorman Salvus rebreather had the same thread as an oxygen storage cylinder, but the opposite gender, for direct decanting.) The storage cylinders are available in a variety of sizes, typically from 50-liter internal capacity to well over 100 liters.

In the more general case, a high-pressure hose known as a filling whip is used to connect the filling panel or storage cylinder to the receiving cylinder.

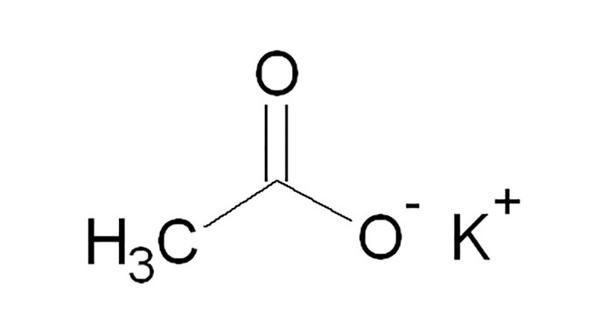

Cascade filling is often used for partial pressure blending of breathing gas mixtures for diving, to economize on the relatively expensive oxygen, for nitrox, and the even more expensive helium in trimix or heliox mixtures.

Compressed natural gas fueling

Cascade storage is used at compressed natural gas (CNG) fueling stations. Typically three CNG tanks will be used, and a vehicle will first be fueled from one of them, which will result in an incomplete fill, perhaps to 2000 PSI for a 3000 PSI tank. The second and third tanks will bring the vehicle’s tank closer to 3000 PSI. The station normally has a compressor, which refills the station’s tanks, using natural gas from a utility line. This prevents accidentally overfilling the tank, which could happen with a system using a single fueling tank at a higher pressure than the target pressure for the vehicle.

Hydrogen storage

In cascade storage systems for hydrogen storage, as for example at hydrogen stations, fuel dispenser A draws hydrogen from tank A, while dispenser B draws fuel from hydrogen tank B. If dispenser A is over-utilized, tank A will become depleted before tank B. At this point the dispenser A is switched to tank C. Tank C will then supply dispenser A and B and tank A until tank A is filled to the same pressure as tank B and the dispensers are disconnected, after which the control system will close the control valves to switch to its former state.

Information Source: