Batteries are portable energy storage devices. They provide power to our headlamps, lanterns, GPS devices, cameras, music players, and other devices. The ideal battery will provide you with a good balance of long life, high performance, low cost, and low environmental impact. To get that, you must first know what you’re looking for, which can be difficult when you start delving into details about electrode, cathodes, and various metal types.

The market for rechargeable batteries is rapidly expanding, but raw materials are scarce. Sodium-ion batteries, for example, could be an option. For this purpose, a joint research group from HZB and Humboldt-Universität zu Berlin investigated new combinations of electrolyte solutions and electrode materials.

We are still at the beginning of our understanding of the implications of co-intercalation batteries. Co-intercalation could improve efficiency by allowing for better low-temperature performance. It could also be used to improve on other cell concepts, such as using multivalent ions instead of Li+ or Na+ storage, which are especially sensitive to the solvation shell.

Dr. Katherine A. Mazzio

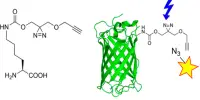

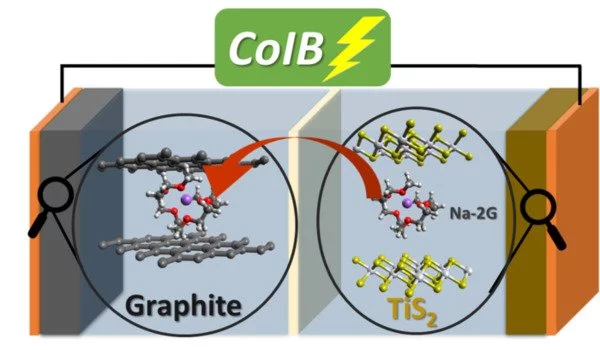

“In contrast to lithium-ion batteries, which are based on the storage of lithium ions in the positive and negative electrodes of the battery, we are working with sodium ions, which are also found in cheap table salt. On the other hand, we store the sodium ions along with their solvate shell, which is made up of solvent molecules from the electrolyte solution that separates the two electrodes. This enables the realization of completely new storage reactions,” explains Prof. Philipp Adelhelm, who leads the research group “operando battery analysis, “which was established in 2020 by Humboldt University and Helmholtz-Zentrum Berlin.

The storage of ions when accompanied by their solvation shell in a crystal lattice is referred to as co-intercalation. Up to this point, this concept was limited to the negative electrode of the sodium-ion battery. Now the researchers around Adelhelm have succeeded in extending the concept to the positive electrode of the battery.

Dr. Guillermo A. Ferrero, first author of the publication, explains: “With titanium disulphide and graphite, we have for the first time combined two materials that absorb and release the same solvent during charging and discharging of the battery.”

The scientists were able to observe changes in the material during charging and discharging by using operando measurements on the LIMAX 160 at HZB’s X-Ray Core Lab. This aided them in locating the co-intercalation mechanism within the battery. They could then apply what they’ve learned to create a battery with two electrodes that rely on reversible co-intercalation of solvent molecules.

“We are still at the beginning of our understanding of the implications of co-intercalation batteries. However, there are a few potential benefits that we can envision.” HZB Dr. Katherine A. Mazzio explains: Co-intercalation could improve efficiency by allowing for better low-temperature performance. It could also be used to improve on other cell concepts, such as using multivalent ions instead of Li+ or Na+ storage, which are especially sensitive to the solvation shell.”