The University of Massachusetts Amherst and the University of North Texas have collaborated on new study that deepens our understanding of how the wood in our homes and workplaces can produce formaldehyde, a powerful carcinogen, at amounts that may be unsafe for human health.

The research, which was just published in Green Chemistry, has the potential to improve public health, and the team has already applied for a patent on a method of reducing the harm caused by formaldehyde.

A powerful carcinogen, formaldehyde is a colorless, odorless gas. Some kinds of cancer and leukemia have been connected to even modest exposure levels. It is well recognized that some manufactured household items, like carpets, drapes, and particleboard, can leak formaldehyde into living areas.

Formaldehyde can be released by wood itself, and treating wood at high temperatures is known to generate significant amounts of the chemical. But it turns out that even at room temperature, wood, especially the wooden furniture and woodwork in our homes, can produce small amounts of formaldehyde.

“This low-level release had been understood for some time now, but no one really knew how that formaldehyde was being produced,” says Barry Goodell, professor of microbiology at UMass Amherst and one of the paper’s senior authors. Until now.

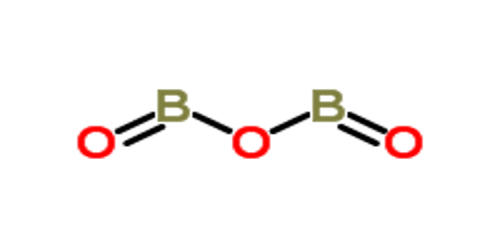

The key is a chemical phenomenon, which the authors have described as a “lignin-mediated Fenton reaction.”

The invention is simple and low cost and could easily be incorporated into the existing wood processing lines so that high quality and environmentally friendly wood products are produced. The formaldehyde control methods we have developed should also be safe for application at home, too, so that homeowners can easily use the systems in the house for air quality improvement.

Sheldon Shi

This is how it works in the case of wood: Lignin, a chemical that makes tough cell walls, gives wood its “woodiness,” rigidity, and stiffness. Iron is one of the most prevalent elements on earth, and because trees are grown in soil, they are continually absorbing trace amounts of iron, which settle in the wood.

Even more iron atoms are pushed into the wood’s surface when the tree is cut down and transformed into lumber using iron-containing equipment like saws and planers. The iron is subsequently altered by lignin, creating a kind of highly reactive iron.

Formaldehyde is produced when lignin and this highly reactive iron interact to make corrosive oxygen radicals, which then seep out of the wood and into the air, where they enter our lungs.

This discovery marks a significant advancement in our knowledge of the room-temperature formation of formaldehyde from wood and wood surfaces. But that’s not all.

“Once we understood how this lignin-mediated Fenton reaction worked, and how it was at play in the wood,” says Goodell, “we had some guesses as to how we might keep the reaction from occurring.”

Simple “chelators” that tie up iron that are frequently found in meals could stop iron from reacting with its environment. These substances are regularly found in foods, such as the breakfast cereals that contain antioxidants to keep them fresh.

As it turns out, the team’s experimental work verified their findings with these food-safe compounds and these ingredients are the building block of a patent that Goodell and his University of North Texas colleague and co-author, Sheldon Shi, recently filed.

The researchers have demonstrated that the release of formaldehyde can be reduced and brought to acceptable levels by merely mixing these antioxidants and chelators with wood, or, in certain cases, spraying them on wood surfaces. It might be able to reduce formaldehyde in commercial wood-based products as well.

“The invention is simple and low cost and could easily be incorporated into the existing wood processing lines so that high quality and environmentally friendly wood products are produced,” said Shi.

“The formaldehyde control methods we have developed should also be safe for application at home, too, so that homeowners can easily use the systems in the house for air quality improvement.”

In order to limit formaldehyde release from items in the home and office, Goodell and Shi are seeking collaborators who are interested in lowering the production of the chemical from wood and wood-based products.