An algal bioreactor is a device that grows and harvests algae for a variety of applications, including biofuel production, wastewater treatment, food additives, and other industrial uses. It is used to grow micro- or macroalgae. Algae can be grown to provide biomass (as in a seaweed cultivator), clean wastewater, fix CO2, or provide aquarium/pond filtration in the form of an algae scrubber.

Algae are photosynthetic organisms capable of converting sunlight and carbon dioxide into biomass via photosynthesis. Algae bioreactors provide regulated settings that promote optimal algae growth and output.

The design of algae bioreactors varies greatly, with two main types: open reactors and enclosed reactors. Open reactors are open to the atmosphere, whereas enclosed reactors, also known as photobioreactors, are isolated to varied degrees from the atmosphere. Algae bioreactors can be used to produce fuels such as biodiesel and bioethanol, animal feed, and to reduce pollutants like NOx and CO2 in power plant flue gases.

Here are some key components and features commonly found in algae bioreactors:

- Culture System: The bioreactor contains a culture system where algae are grown. This system may use open ponds, closed photobioreactors, or a combination of both, depending on the specific application.

- Light Source: Algae require light for photosynthesis. Artificial light sources, such as LED or fluorescent lights, are often used in closed bioreactors to control and optimize light exposure.

- Carbon Source: Algae need carbon dioxide (CO2) for photosynthesis. Some bioreactors introduce CO2 artificially, while others use waste gases from industrial processes or carbon capture technologies.

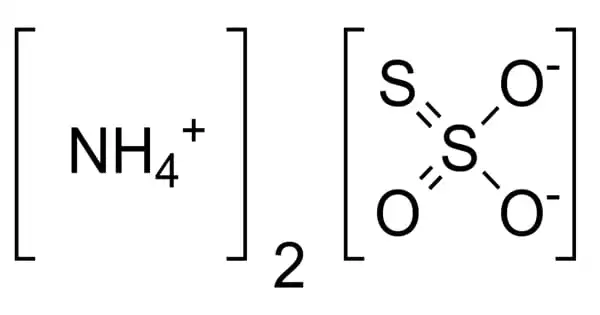

- Nutrient Supply: Algae need essential nutrients like nitrogen and phosphorus for growth. These nutrients can be supplied through nutrient solutions or from sources like wastewater.

- Temperature Control: Maintaining optimal temperature is crucial for algae growth. Bioreactors often include temperature control systems to regulate the culture environment.

- Mixing and Aeration: Adequate mixing and aeration ensure uniform distribution of nutrients, light, and carbon dioxide throughout the algae culture. This promotes even growth and prevents settling.

- Harvesting System: Once the algae reach a desired biomass concentration, they need to be harvested. Different methods, such as centrifugation, filtration, or flocculation, can be used for harvesting algae from the culture.

Algae bioreactors have gained popularity due to algae’s promise as a renewable resource. They can be used to produce biofuels such as biodiesel because algae are high in lipids. Algae can also be used to remediate wastewater since they absorb nutrients and contaminants.

Fundamentally, this type of bioreactor is based on the chlorophyll-containing algae’s photosynthetic process, which uses dissolved carbon dioxide and sunlight. The carbon dioxide is spread in the reactor fluid, making it available to the algae. The bioreactor must be made of transparent material.