Hydrocyclones are machines that classify, separate, and concentrate particles in a liquid solution depending on size, density, and form. These are cyclonic separators that separate product phases primarily based on gravity differences and use aqueous solutions as the principal feed fluid. They are widely used in a variety of industries, including mining, oil and gas, water treatment, and environmental engineering.

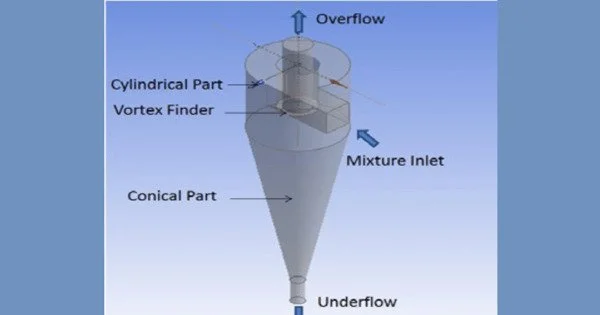

A hydrocyclone’s principal function is to separate or categorize particles from a liquid mixture using centrifugal forces. Hydrocyclones are different from dry or dust cyclones in that they separate solids or various phase fluids from the bulk fluid. A hydrocyclone comprises a cylindrical-shaped feed part with tangential feed; an overflow part with a vortex finder; and a conical part with an apex. A cyclone has no moving parts.

Working principle

The product is injected tangentially into the hydrocyclone at a specific pressure. This causes a centrifugal action, pushing the heavier phase outward and downward along the wall of the conical section. The decreasing diameter in the conical portion increases the speed and hence improves separation. Finally, the concentrated solids are ejected via the apex. The vortex finder in the overflow section causes a fast rotating upward spiral movement of the fluid in the center of the conically shaped housing. The fluid is drained via the overflow exit.

Here’s a brief overview of how hydrocyclones work:

- Inlet Section: The mixture containing particles is introduced into the hydrocyclone through an inlet pipe.

- Tangential Entry: The liquid is forced to rotate within the hydrocyclone, creating a strong centrifugal force. This rotation is typically achieved by introducing the liquid tangentially into the cylindrical section of the hydrocyclone.

- Centrifugal Force: Due to the centrifugal force, heavier particles move towards the outer wall of the hydrocyclone, while lighter particles are directed towards the center.

- Underflow and Overflow: As the liquid swirls, two separate streams are formed – the inner, lighter particles form an upward-moving inner vortex (overflow), while the heavier particles move downward and are collected as the underflow.

- Outlet Sections: The separated particles are then discharged through separate outlets for the underflow and overflow.

Key features and advantages of hydrocyclones include:

- Simple Design: Hydrocyclones have a relatively simple design and are easy to install and operate.

- Cost-Effective: They are generally cost-effective compared to other separation technologies.

- Size Classification: Hydrocyclones can effectively classify particles based on their size, making them useful in processes where particle size separation is crucial.

- No Moving Parts: Hydrocyclones do not have any moving parts, which reduces maintenance requirements.

- High Efficiency: They can achieve high separation efficiency for fine particles.

Applications

Hydrocyclones find applications in various industries, such as mineral processing for separating ore particles, oil and gas industry for separating sand and other solids from produced water, and water treatment for removing suspended solids.