Because of its high theoretical capacity and low cost, sodium metal is a promising anode for sodium batteries. However, the severe Na dendrite growth and low Coulombic efficiency, particularly at high current densities/cycling capacities, severely restrict the use of sodium metal anodes.

Sodium secondary batteries work in the same way as lithium secondary batteries, but they are less expensive and are expected to be a powerful supplement to lithium secondary batteries. Solid-state batteries are thought to have promising future prospects due to their high safety and energy density. However, all-solid-state batteries are hampered by poor physical solid-solid interfacial contact and low ionic conductivity, which limit their performance and limit their commercial applicability in the short term.

In situ polymerization has recently been extensively researched for the preparation of solid/quasi-solid electrolytes, allowing for close interfacial contact between the electrolyte and electrodes. Many in situ polymerization systems use a high-temperature free-radical polymerization strategy; however, maintaining high reaction temperatures over time is detrimental to battery performance.

In situ polymerization has recently been extensively researched for the preparation of solid/quasi-solid electrolytes, allowing for close interfacial contact between the electrolyte and electrodes.

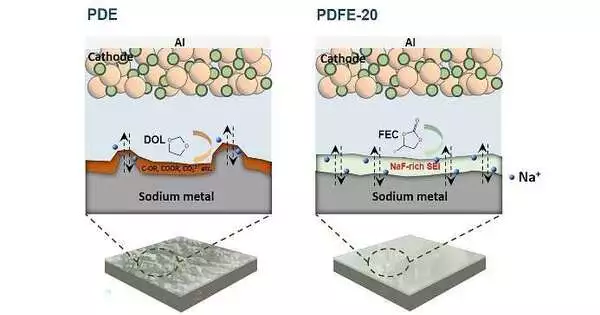

1,3-Dioxolane (DOL) can be polymerized at room temperature via cationically ring-opening reactions to yield poly(1,3-dioxolane) (PDOL), which has high research and application value. DOL has recently been successfully used as an in situ polymerization monomer in lithium metal/lithium sulfur batteries; however, there has been little research into the use of PDOL in sodium metal batteries (SMBs).

In addition, although in situ polymerization strategies can greatly improve the physical contact between the electrolyte and electrodes, it remains challenging to maintain close interfacial contact during battery cycling considering the high reactivity of the Na metal anode.

Recently, Hongfa Xiang’s group from the Hefei University of Technology and David Mitlin’s group from the University of Texas in Austin published a manuscript entitled “Stable sodium anodes for sodium metal batteries (SMBs) enabled by in-situ formed quasi solid-state polymer electrolyte” in the Journal of Energy Chemistry. In this work, based on the interfacial protection strategy, fluoroethylene carbonate (FEC) was introduced into the PDOL system.

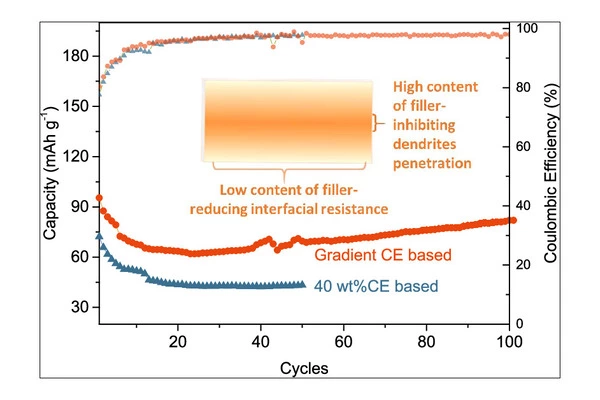

The in situ polymerization method was used to create a PDOL-FEC quasi-solid electrolyte that was successfully applied to SMBs. DOL continuously reacted with the highly chemically active Na metal anode, and the accumulation of reaction products resulted in a high interfacial resistance, severely reducing battery performance. After FEC was introduced, it was reduced at the Na metal anode side prior to DOL addition, forming a NaF-rich passivation layer and inhibiting further side reactions between DOL and the Na metal, effectively improving the batteries’ overall performance.

For meeting the voracious energy demand of human activities, sodium-ion batteries with obvious advantages in resource abundance and expenditure are emerging as a more suitable alternative to lithium-ion batteries. Exploration of anode materials suited to the electrochemical system has never stopped as an integral component of the battery over the last few decades, and the sodium metal anode successfully stands out with its high theoretical capacity and low redox potential.