Multi-walled carbon nanotubes (MWNTs) may now be created on a plastic film at a low cost thanks to research from Japan’s Tokyo University of Science. The suggested process is straightforward, adaptable to ambient circumstances, recycles MWNTs, and creates flexible wires with adjustable resistances without the need for further procedures. It makes flexible all-carbon devices possible by doing away with a number of the disadvantages of the present fabrication techniques.

Carbon nanotubes (CNTs) are cylindrical tube-like structures made of carbon atoms that display highly desirable physical properties like high strength, low weight, and excellent thermal and electrical conductivities. As a result, they make excellent materials for a variety of uses, including electronics, energy storage and conversion systems, and reinforcement materials.

Despite their enormous promise, CNTs have faced difficulties in the commercialization process. One such issue is how to incorporate CNTs onto plastic substrates to create flexible CNT-based devices.

Conventional fabrication techniques need a clean facility and highly controlled settings, such as high temperatures. Further, they require repeat transfers to produce CNTs with different resistance values.

More direct methods such as laser-induced forward transfer (LIFT) and thermal fusion (TF) have been developed as alternatives. In the LIFT method, a laser is used to directly transfer CNTs onto substrates, while in TF, CNTs are mixed with polymers that are then selectively removed by a laser to form CNT wires with varying resistance values.

However, both these methods are expensive and have their unique problems. LIFT requires expensive pulsed lasers and preparation of CNTs with specific resistance values, while TF uses large amounts of CNTs that are not utilized and go to waste.

We expect the process cost to be significantly reduced compared to that for conventional methods. This, in turn, will contribute to the realization of low-cost flexible sensors that are expected to have wide applications in large quantities.

Professor Dr. Takashi Ikuno

Aiming to develop a more simple and inexpensive approach, Associate Professor Dr. Takashi Ikuno along with his collaborators, Mr. Hiroaki Komatsu, Mr. Yosuke Sugita and Mr. Takahiro Matsunami at Tokyo University of Science, Japan, recently proposed a novel method that enables fabrication of multi-walled CNT (MWNT) wiring on a plastic film under ambient conditions (room temperature and atmospheric pressure) using a low-cost laser.

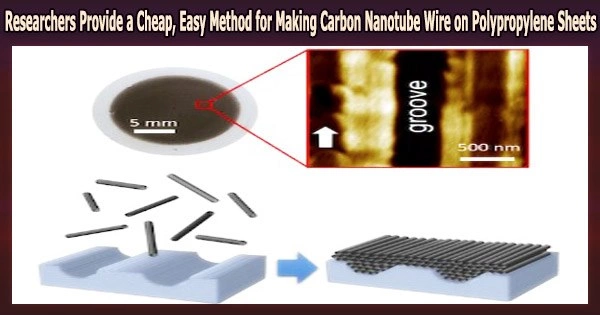

The breakthrough, published in the journal Scientific Reports on 08 February 2023, involves coating a polypropylene (PP) film with an MWNT film about 10 μm thick and then exposing it to a mW UV laser. The result is a conductive wiring made of a combination of MWNT and PP.

“This process enables the easy ‘drawing’ of wiring and flexible devices for wearable sensors without the need for complex processes,” highlights Dr. Ikuno.

The differential in thermal conductivities between the MWNT and the PP film, according to the researchers, is what caused the development of these wires. As the MWNT/PP film is exposed to the laser, the high thermal conductivity of the MWNT layer causes the heat to spread along the length of the wire, resulting in high temperatures at the MWNT-PP interface and lower temperatures elsewhere in the PP film.

Directly below the laser, where temperatures are the highest, the PP diffuses into the MWNT film to form a thick PP/MWNT composite, while a thin PP/MWNT layer is formed at the edges of the laser where temperatures are relatively low.

By simply altering the irradiation settings, the suggested method also enables the manufacturing of carbon wires with various resistance values throughout the same process (without repeat transfer), obviating the need for extra steps.

Exposing the PP/MWNT film to high laser energies, achieved either by low scanning speeds, a high number of laser exposures, or the use of a high-powered laser, produces thicker wires with a higher concentration of MWNTs.

Consequently, the lower resistivity of MWNT and the thicker wire lowers the resistance per unit length of the wire (resistance is directly proportional to the ratio between the resistivity and the thickness of the wire).

By precisely controlling the exposure of the MWNT/PP film to laser light, the researchers successfully fabricated MWNT wires with a wide range of resistance values, from 0.789 kΩ/cm to 114 kΩ/cm. Moreover, these wires were highly flexible and maintained their resistance even when bent repeatedly.

The technology also addressed a critical shortcoming of existing approaches, notably the inability of LIFT and TF procedures to reuse CNTs not used in the production process.

The suggested technique enables the recovery and reuse of MWNTs that are not incorporated into the PP film during laser irradiation, enabling the production of fresh MWNT wires with little to no change in resistance values.

The new technology has the potential to implement large-scale manufacturing of flexible carbon wiring for flexible sensors and energy conversion and storage devices due to its simplicity, effective use of CNTs, and capacity to produce high-quality wires.

“We expect the process cost to be significantly reduced compared to that for conventional methods. This, in turn, will contribute to the realization of low-cost flexible sensors that are expected to have wide applications in large quantities,” concludes Dr. Ikuno.