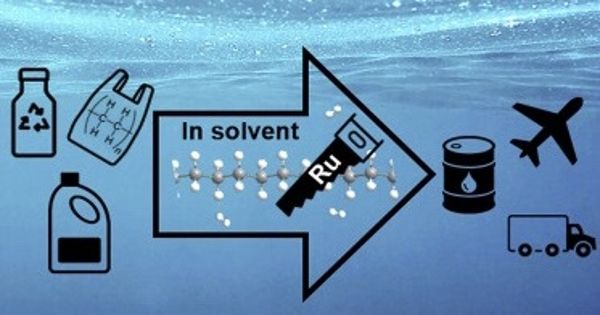

Researchers have devised a novel method for converting plastics into ingredients for jet fuel and other valuable products, making the reuse of plastics easier and more cost-effective. In their reaction, the researchers were able to convert 90 percent of plastic to jet fuel and other valuable hydrocarbon products in an hour at moderate temperatures and easily fine-tune the process to create the desired products.

In their reaction, the researchers were able to convert 90 percent of plastic to jet fuel and other valuable hydrocarbon products in an hour at moderate temperatures and easily fine-tune the process to create the desired products. They report on their work in the journal Chem Catalysis, led by graduate students Chuhua Jia and Hongfei Lin, associate professor in the Gene and Linda Voiland School of Chemical Engineering and Bioengineering.

“The cost of recycling is critical in the recycling industry,” Lin explained. “This work is a watershed moment for us as we work to commercialize this new technology.”

Washington State University researchers have developed an innovative way to convert plastics to ingredients for jet fuel and other valuable products, making it easier and more cost-effective to reuse plastics.

According to all accounts, the problem of waste plastic is a global crisis. According to the World Economic Forum, 10 million tons of plastic waste end up at sea each year. Much of this ends up in the massive Pacific Garbage Patch, which is expanding at an exponential rate despite the best efforts of initiatives like the Ocean Voyages Institute, the Ocean Cleanup Project, and novel ideas like the plastic-collecting ‘Manta’ catamaran.

The accumulation of waste plastics has caused an environmental crisis in recent decades, polluting oceans and pristine environments all over the world. Microplastics have been found to enter the food chain as they degrade, posing a potential, if unknown, a threat to human health.

Recycling plastics, on the other hand, has proven difficult. The most common mechanical recycling methods melt and re-mold the plastic, which reduces its economic value and quality for use in other products. Chemical recycling can result in higher-quality products, but it requires high reaction temperatures and a long processing time, making it prohibitively expensive and time-consuming for industries to implement. Because of its limitations, only about 9% of plastic in the U.S. is recycled every year.

The WSU researchers developed a catalytic process to efficiently convert polyethylene to jet fuel and high-value lubricants in their work. Polyethylene, also known as #1 plastic, is the most widely used plastic, appearing in a wide range of products ranging from plastic bags, milk jugs, and shampoo bottles to corrosion-resistant piping, wood-plastic composite lumber, and plastic furniture.

The researchers used ruthenium on carbon catalyst and a common solvent in the process. They were able to convert approximately 90% of the plastic to jet fuel components or other hydrocarbon products in less than an hour at a temperature of 220 degrees Celsius (428 degrees Fahrenheit), which is more efficient and lower than typical temperatures.

Jia was astounded by how well the solvent and catalyst worked. “Before the experiment, we only speculated but had no idea if it would work,” he explained. “The end result was fantastic.”

Adjusting processing conditions, such as temperature, time, or the amount of catalyst used, provided a critical step in fine-tuning the process to produce desirable products, according to Lin.

“They can tune to what product they want to generate based on the market,” he said. “They are adaptable. The use of this efficient process could provide a promising method for selectively producing high-value products from waste polyethylene.”

The researchers are working to scale up the process for future commercialization with the help of the Washington Research Foundation. They also believe their method could be applied to other types of plastics.

The study was carried out in collaboration with researchers from the University of Washington and the Pacific Northwest National Laboratory, including Professor Jim Pfaendtner. The Washington State Research Foundation and the National Science Foundation funded it.

The next step for the researchers is to scale their process so that it can be commercialized in the future. They also intend to conduct experiments with other plastics in order to expand their process’s ability to address even more of the world’s plastic waste.