In Science Advances, researchers from the University of Bayreuth propose novel electrospun nonwovens with an uncommon combination of excellent electrical conductivity and extremely low thermal conductivity.

The nonwovens represent a milestone in materials research: electrical and thermal conductivity may now be decoupled using a basic material idea.

Nonwovens refer to a class of textile materials that are manufactured by bonding or interlocking fibers together without the use of a weaving or knitting process. Instead, nonwoven fabrics are made by techniques such as air-laid, spunbond, meltblown, or needle-punching.

The nonwovens are created by electrospinning carbon and silicon-based ceramics and are appealing for technical applications such as energy technology and electronics.

Nonwovens have a wide range of applications across various industries, including healthcare, hygiene, automotive, construction, and filtration. They can be manufactured and processed cost-effectively on an industrial scale.

High electrical conductivity is typically coupled with high thermal conductivity, while low thermal conductivity is related with poor electrical conductivity. However, there is growing interest in multifunctional materials that combine good electric with low thermal transport in many high-tech industries.

Our electrospun nonwovens combine highly attractive multifunctional properties that are usually distributed among different classes of materials: high electrical conductivity, thermal insulation familiar from polymer foams, and non-flammability and heat resistance characteristic of ceramics. The fibers are based on a simple material concept, and they were made from commercial polymers.

Dr. Xiaojian Liao

Though several materials strategies, such as dense inorganic materials, conjugated polymers, and alloys, have been developed, achieving extremely low thermal conductivity in combination with high electrical conductivity remains a major challenge for flexible, foldable materials.

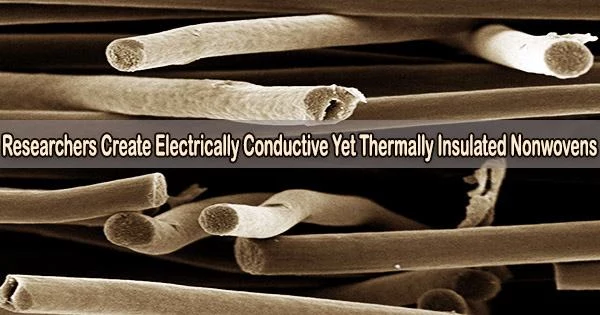

The University of Bayreuth’s research team has identified a novel solution to this problem: new electrospun nonwovens composed of carbon and silicon-based ceramic and consist of fibers with a sea-island type nanostructure and a diameter between 500 and 600 nanometers.

Every fiber has a carbon matrix with homogeneously distributed nano-sized ceramic phases. The particles form tiny “islands” in the “sea” of carbon matrix and have opposite, complementary effects.

The carbon matrix allows electron movement and hence strong electrical conductivity in the fibers, while the nano-sized silicon-based ceramic prevents thermal energy from spreading as easily.

This is due to the strong contact between the nano-sized ceramic and the carbon matrix, whilst the pores of the nonwoven are quite small. As a result, phonons, the smallest physical units of vibrations caused by heat energy, are strongly scattered. A continuous directed heat flow does not occur.

A comparison with over 3,900 materials of all types, including ceramics, carbons, natural materials, synthetic polymers, metals, glasses, and diverse composites, highlights the uncommon combination of strong electrical and extremely low thermal conductivity. The new electrospun composite fiber material was more tightly connected with electron transport and thermal energy insulation than the other materials.

“Our electrospun nonwovens combine highly attractive multifunctional properties that are usually distributed among different classes of materials: high electrical conductivity, thermal insulation familiar from polymer foams, and non-flammability and heat resistance characteristic of ceramics. The fibers are based on a simple material concept, and they were made from commercial polymers,” says first author Dr. Xiaojian Liao, a postdoctoral researcher in macromolecular chemistry at the University of Bayreuth.

“We are convinced that our new fibers are suited for several application areas: for example, in the fields of energy management, battery-powered electromobility, smart textiles, or aerospace,” says Prof. Dr. Seema Agarwal, professor of macromolecular chemistry at the University of Bayreuth and one of the corresponding authors of this new study.

This work was made possible by an interdisciplinary team at the University of Bayreuth with competence in ceramics, polymers, electrospinning, physical chemistry, and electron microscopy.