Potassium alum, potassium alum, or potassium aluminum sulfate is a metal sulfate consisting of ions of potassium, aluminium, and sulfate in a 1:1:2 rations. As a flame retardant, mordant and astringent, it has a place. It is a chemical compound with the chemical formula KAl(SO4)2: double potassium and aluminium sulphate. It is a metal sulfate, a salt of aluminum, and a salt of potassium and it contains aluminum (3+). It is usually found as the KAl(SO4)2•12H2O dodecahydrate.

In homes and workplaces, aluminum is the most commonly available material. From the use of food additives, antacids, buffered aspirin, astringents, nasal sprays, and antiperspirants; from drinking water; from vehicle exhaust and cigarette smoke; and from the use of aluminum foil, aluminum cookware, containers, ceramics, and fireworks, it is readily accessible for human consumption. Potassium alum is taken into account by the FDA as generally recognized as a safe (GRAS) substance. It crystallizes in a cubic structure with space group P a -3 and lattice parameter of 12.18 Å. The compound is that the most significant member of the generic class of compounds called alums, and is commonly called simply alum.

Crystals of Potassium Alum

A white crystal that is soluble in water is aluminium potassium sulfate dodecahydrate. It is produced in a furnace by roasting alunite and then by crystallization harvesting the product. Potassium alum is made up of large, transparent crystals that are used as a buffer, neutralizing, or forming agent in various products, such as food or medicines. Potassium alum is usually used as E number E522 in water purification, leather tanning, dyeing, fireproof textiles, and baking powder. As a deodorant, as an aftershave cream, and as a styptic for minor bleeding from shaving, it also has cosmetic applications.

By treating bauxite with sulfuric acid and then potassium sulfate, potassium alum is made. Alternatively, potassium sulfate is used to react with aluminum sulfate. The Ancient Egyptians were believed to have obtained it from evaporites in the Western desert and reportedly used it to minimize the apparent cloudiness (turbidity) in the water as early as 1500 BCE. The production of double salt from alunite is archaeologically attested on the island Lesbos. This site was abandoned within the 7th century but dates back a minimum of to the 2nd century CE. The first example contains potassium and aluminium (called aluminium orsimply alum); its formula is often written AlK(SO4)2.12H2O (aluminium potassium sulfate-12-water).

Alum is a strong astringent and precipitates proteins. This can be used as a hemostatic for superficial abrasions and cuts and ulcers on the lips as either a solid or as a solution. The alums are isomorphic and can be formed in water and recrystallized by dissolving equal quantities of the two salts. When heated to almost a high temperature, it gives a porous, friable mass, which is understood as “burnt alum”. It fuses at 92 °C (198 °F) in its own water of crystallization.

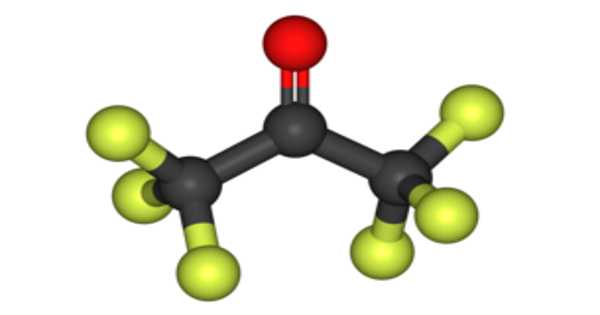

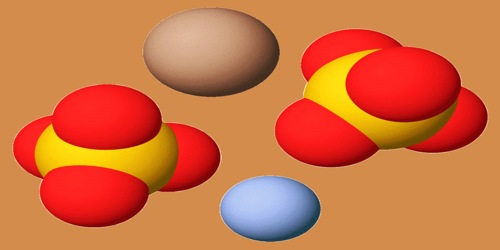

Chemical structure of potassium alum

For application to the umbilical cord, Pediatric Alum and Zinc Dusting-powder were used; it is not appropriate for use as a general dusting-powder. By adding potassium sulfate to a concentrated aluminium sulfate solution, potassium alum is now developed industrially. Aluminium sulfate is typically obtained by treating sulfuric acid with minerals such as alum schist, bauxite, and cryolite. If the sulfate contains a lot of iron, then it is better to use potassium chloride instead of potassium sulfate.

Potassium alum is commonly included in preparations used as mouthwashes or gargles and in dermatological preparations. Large doses of double salt act as an irritant and will be corrosive; gum necrosis and gastrointestinal hemorrhage have occurred. In antacids, antidiarrheals, and defensive dermatological pastes, aluminum, and its salts are used medicinally. It is also used in deodorants and cosmetics. Potassium alum is incompatible with aluminum, copper, steel, and zinc, which are potent oxidizing agents. Gray or green colors can develop due to traces of iron in the alum when dispensed in powders containing phenol, salicylate, or tannic acid.

In order to have a second leavening step at high temperatures, potassium alum may be an acidic component in baking powder (although sodium alum is more widely used for this reason. Potassium alum does not go through a metabolic cycle. It will easily dissolve when consumed or absorbed, and it will form ions that will produce other salt derivatives later. Potassium alum is also a weak irritant to the skin.

Information Sources: