Polyamide-imides are amorphous, thermosetting or thermoplastic polymers with outstanding mechanical, thermal, and chemical resistance. These are a type of high-performance engineering thermoplastic with exceptional mechanical, thermal, and chemical qualities. They have strong heat resistance, mechanical strength, and chemical resistance, making them appropriate for a wide range of demanding applications in industries such as aerospace, automotive, electronics, and others.

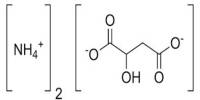

Polyamide-imides are widely employed as wire coatings in the manufacture of magnet wire. They are made in N-methyl-2-pyrrolidone (NMP) from isocyanates and TMA (trimellic acid-anhydride). Solvay Specialty Polymers, under the brand Torlon, is a major distributor of polyamide-imides.

Polyamide-imides combine the features of polyamides and polyimides, such as high strength, melt processibility, outstanding high heat capacity, and extensive chemical resistance. Polyamide-imide polymers can be processed into a wide range of products, including injection and compression molded parts and ingots, coatings, films, fibers, and adhesives. In most cases, these items reach their peak qualities after a further thermal cure step. Polyetheretherketones and polyimides are two other high-performance polymers in this class.

Here are some key characteristics and features of polyamide-imides:

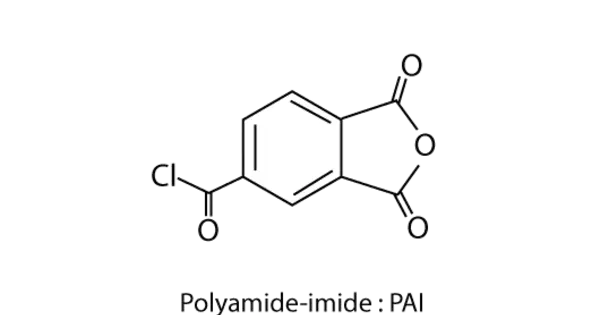

- Chemical Structure: PAIs are typically made through condensation polymerization of a diamine and a dianhydride. This produces a polymer chain with both amide and imide functional groups, hence the term “polyamide-imide.”

- High Temperature Resistance: One of the most notable characteristics of PAIs is their high heat resistance. They can tolerate continuous operation at high temperatures, frequently up to 300°C (572°F). This feature qualifies them for applications involving frequent exposure to high temperatures.

- Mechanical Properties: PAIs exhibit outstanding mechanical qualities, including as high tensile strength, stiffness, and impact resistance. Even at high temperatures, they retain their strength and dimensional stability, which is crucial in demanding industrial applications.

- Chemical Resistance: PAIs are highly resistant to a wide range of chemicals, including acids, bases, solvents, and fuels. This chemical resistance makes them suitable for use in environments where exposure to corrosive substances is a concern.

- Electrical Properties: Polyamide-imides exhibit good electrical insulating properties, which makes them suitable for electrical and electronic applications.

- Low Outgassing: In aerospace and vacuum applications, PAIs are favored for their low outgassing characteristics, which means they release minimal volatile compounds when exposed to vacuum conditions. This property is essential in spacecraft and other vacuum-sealed environments.

- Machinability: While PAIs are well-known for their good characteristics, their high melting temperatures and hardness make them difficult to treat and machine. It is possible that specialized equipment and machinery will be required.

Applications

Polyamide-imides are used in a variety of applications such as aircraft components, automotive parts, electrical connectors, high-temperature seals and gaskets, and industrial equipment.