New study by University of Sussex physicists will ‘significantly enhance’ the new technology area of liquid electronics, improving the usefulness and sustainability of prospective applications in printed electronics, wearable health monitoring, and even batteries.

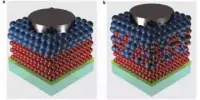

The Sussex scientists improved on their prior work wrapping emulsion droplets with graphene and other 2D materials by lowering the coatings down to atomically thin nanosheet layers in their study report published in ACS Nano.

They were able to build electrically-conducting liquid emulsions with the lowest-loading graphene networks yet recorded at just 0.001 vol% as a result of their efforts.

This means that future liquid electronic technology, such as strain sensors to track physical performance and health, electronic devices printed from emulsion droplets, and even potentially more efficient and long-lasting electric vehicle batteries, will be both cheaper and more sustainable because they will use less graphene or other 2D nanosheets to coat the droplets.

Another significant advancement is that the scientists can now create these electronic droplet networks with any liquid, whereas previous research had focused on conventional oils and water, because they have discovered how to control which liquid droplets are wrapped in graphene, allowing them to tailor the emulsions to the application.

Carbon atoms are closely bonded in a hexagonal honeycomb lattice to form graphene, which is a single layer (monolayer). It’s a carbon allotrope with a molecular bond length of 0.142 nanometres and a plane of sp2-bonded atoms.

At one atom thick, graphene is the thinnest material known to man, and it’s also 200 times stronger than steel. Graphite is made up of layers of graphene stacked on top of each other with an interplanar spacing of 0.335 nanometres.

The potential of 2D materials, such as graphene, is in their electronic properties and their processability; we developed a process to harness the surface area of our nanosheet dispersions to stabilise emulsion droplets with ultra-thin coatings.

Dr. Sean Ogilvie

Silicon, III-V, and II-VI semiconductor manufacturing methods have improved to the point where they can build integrated circuits with gate widths of less than 10 nanometers. The most modern 3D printing techniques currently available provide near micron-level resolution and multi-material co-deposition.

Dr. Sean Ogilvie, Research Fellow in Material Physics and lead author of the paper at the University of Sussex School of Mathematical and Physical Science, explains the science behind the development:

“The potential of 2D materials, such as graphene, is in their electronic properties and their processability; we developed a process to harness the surface area of our nanosheet dispersions to stabilise emulsion droplets with ultra-thin coatings.”

“The tuneability of these emulsions allows us to wrap 2D materials around any liquid droplets to exploit their electronic properties. This includes emulsion inks, in which, we’ve discovered that droplets can be deposited without the coffee ring effect which hinders printing of conventional functional inks, potentially enabling single-droplet films for printed transistors and other electronic devices.”

“Another exciting development for our research group is that we can now also design and control our emulsions towards specific applications such as wrapping soft polymers such as silicone for wearable strain sensors that exhibit increased sensitivity at low graphene loading, and we are also investigating emulsion assembly of battery electrode materials to enhance the robustness of these energy storage devices.”

Van der Waals forces hold the individual layers of graphene in graphite together, which can be overcome during graphene exfoliation. Graphene is a good heat and electrical conductor with unique light absorption properties.

It is truly a material that has the potential to revolutionize the world, with limitless applications in practically every industry. Wearable technology that uses sensors to track how the body moves provides users with information about themselves.

Wearables can now measure more accurately thanks to advances in sensor technology. As a result, consumers have a better understanding of themselves and can make lifestyle adjustments as a result.

Professor of Experimental Physics at the University of Sussex, Alan Dalton, explains why this breakthrough is fascinating. He was first prompted to investigate the prospect of adding graphene to liquid emulsions by the preparation of a salad dressing:

“In bringing the graphene coatings of the liquid droplets down to atomically-thin layers and in opening wide the potential for real-world applications by being able to do so with any liquid material, this research development will significantly advance the emerging and scientifically exciting field of liquid electronics.”