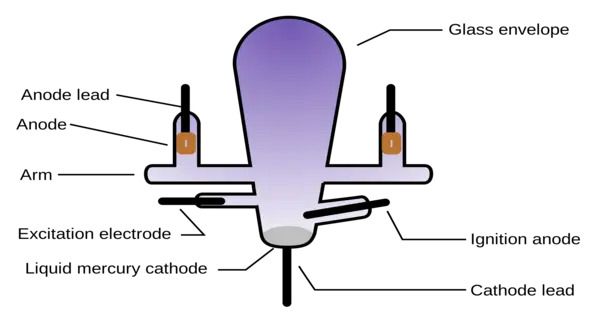

A mercury-arc valve, also known as a mercury-vapor rectifier or (in the United Kingdom) mercury-arc rectifier, is a type of electrical rectifier that converts high-voltage or high-current alternating current (AC) to direct current. It is a type of electrical rectifier that converts high-voltage or high-current alternating current (AC) to direct current. These devices were widely utilized in industrial applications beginning in the early twentieth century and were mostly displaced by solid-state rectifiers by the mid-century.

It is a cold cathode gas-filled tube that is unique in that the cathode is built from a pool of liquid mercury rather than a solid, making it self-restoring. As a result, when utilized properly, mercury-arc valves are significantly more robust and durable, with the ability to transmit far larger currents than most other forms of gas discharge tubes. Some instances have remained in continuous use for decades, correcting 50-ampere current.

Mercury-arc rectifiers, invented in 1902 by Peter Cooper Hewitt, were used to power industrial motors, electric trains, streetcars, electric locomotives, radio transmitters, and high-voltage direct current (HVDC) power transmission.

Principle of Operation

- Mercury Pool Cathode: The mercury-arc valve is made up of a pool of liquid mercury at the bottom of a sealed glass or metal envelope. The mercury functions as the cathode.

- Anodes: Several anodes are positioned above the mercury pool. These are often composed of graphite or metal.

- Arc Formation: When an AC voltage is given to the device, an arc forms between the mercury pool (cathode) and the anode. This arc permits current to flow from the anode to the cathode but not in the reverse way, resulting in rectification.

- Ionization: The arc ionizes the mercury vapor within the envelope, forming a conductive route for electricity. The mercury ions and electrons aid in the transfer of power from the anode to the cathode.

Key Features

- High Current Capability: Mercury-arc valves can handle very high currents, making them suitable for industrial applications like electric railways and power conversion stations.

- Efficiency: They have higher efficiency compared to some earlier rectification methods, though less efficient than modern solid-state devices.

- Durability: These valves are robust and can operate for extended periods under heavy loads.

Applications

- Power Conversion: They were used in power stations for converting AC generated by power plants into DC for distribution over long distances, which was then converted back to AC using motor-generator sets.

- Industrial Electrolysis: Used in processes like the electrolysis of aluminum and other electrochemical processes.

- Electric Railways: Used in traction systems to supply DC power to electric trains.

Safety and Environmental Concerns

- Toxicity: Mercury is highly toxic, and the handling and disposal of mercury-arc valves require special precautions to prevent environmental contamination and health risks.

- Obsolescence: With the advent of solid-state technology, mercury-arc valves are now largely obsolete but can still be found in some specialized applications or historical installations.