Organic solar cells (OSCs) have the potential to be a low-cost, flexible replacement for traditional inorganic solar cells. Obtaining high power conversion efficiencies (PCEs) while maintaining stability over time has been one of the challenges of OSCs.

The photoactive layer of organic solar cells is composed of polymers and small molecules. The cells are very thin, flexible, and simple to create. However, the efficiency of these cells remains significantly lower than that of traditional silicon-based cells.

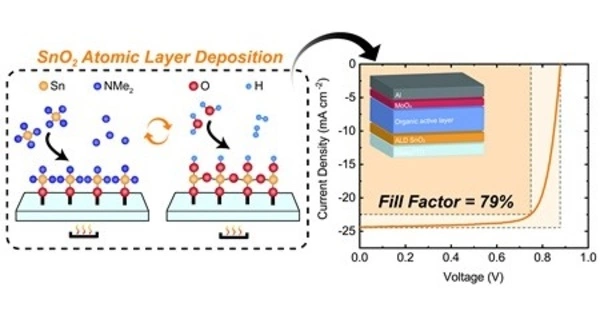

Applied physicists from the University of Groningen have now created an organic solar cell with an efficiency of more than 17%, which is near the top of the range for this material. It has the advantage of employing a novel device structure that is created using a scalable method. A conductive layer of tin oxide is grown using atomic layer deposition in the design. The researchers also have several ideas for improving the cell’s efficiency and stability. The results have been described in the journal Advanced Materials.

Polymers and small molecules in organic solar cells convert light into charges that are collected at the electrodes. These cells are created by stacking thin films of different layers, each with its own set of properties, onto a substrate. The photoactive layer, which converts light into charges and separates electrons from holes, and the transport and blocking layer, which selectively directs electrons towards the electrode, are the most important.

Our aim was to make organic solar cells more efficient and to use methods that are scalable. The efficiency is close to the current record for organic solar cells, which stands around 19 percent. And we haven’t optimized the other layers yet. So, we need to push our structure a bit further.

Garcia Romero

Stability

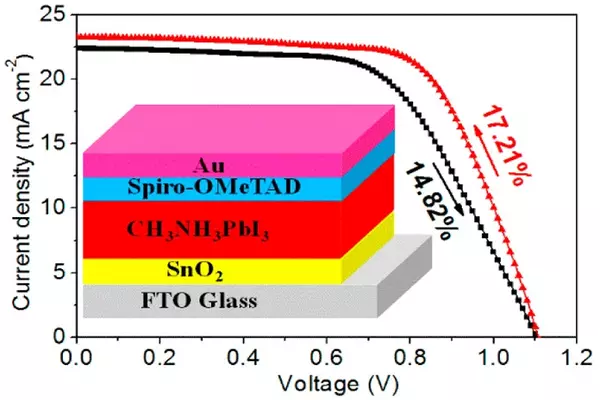

‘In most organic solar cells, the electron transport layer is made of zinc oxide, a highly transparent and conductive material that lies beneath the active layer,’ says David Garcia Romero, a Ph.D. student in Professor Maria Antonietta Loi’s Photophysics and Optoelectronics group at the Zernike Institute for Advanced Materials at the University of Groningen. Garcia Romero collaborated with Lorenzo Di Mario, a postdoctoral researcher in the same group, on the idea of using tin oxide as the transport layer. ‘Because zinc oxide is more photoreactive than tin oxide, the latter should result in higher device stability,’ he explains.

Although tin oxide had previously shown promising results, the best way to grow it into a suitable transport layer for an organic solar cell had not yet been discovered. ‘We used atomic layer deposition, which had not been used in the field of organic photovoltaics in a long time,’ Garcia Romero explains. It does, however, have some significant advantages: ‘This method can produce layers of exceptional quality and is scalable to industrial processes, such as roll-to-roll processing.

Scalable

The organic solar cells with tin oxide deposited on top by atomic layer deposition perform admirably. ‘We achieved a champion efficiency of 17.26 percent,’ says Garcia Romero. The fill factor, an important parameter of solar cell quality, showed values up to 79 percent, which is consistent with previous records for this type of structure. Furthermore, the optical and structural properties of the tin oxide layer could be tuned by varying the temperature at which the material is deposited.

Maximum power conversion was achieved in cells with a transport layer deposited at 140 degrees Celsius. The same result was obtained for two different active layers, indicating that the tin oxide improved efficiency in general.

‘Our aim was to make organic solar cells more efficient and to use methods that are scalable,’ says Garcia Romero. The efficiency is close to the current record for organic solar cells, which stands around 19 percent. ‘And we haven’t optimized the other layers yet. So, we need to push our structure a bit further.’ Garcia Romero and his co-author Lorenzo di Mario are also keen to try making larger area cells. These are typically less efficient but are needed to step towards real-world applications and panels.

Improvement

The new solar cell with an impressively high fill factor is an excellent starting point for future research. Garcia Romero (Spanish): ‘It may be a bit early for industrial partners to take this on; we need to do some more research first. We also hope that our use of atomic layer deposition will serve as an inspiration to others in the field. Professor Loi continues, “We always strive to understand what is happening in a material and in a device structure.”

‘We believe there is room for improvement here. Our tin oxide transport layer is an excellent first step in that process.’ Because of their mechanical properties and transparency, this class of solar cells may make an important additional contribution to the energy transition. ‘We expect that they will be used in a totally different way than silicon panels,’ says Loi. ‘We need to think broader and out of the box at the moment.’