An oil water separator (OWS) is a piece of equipment that separates oil and water mixtures into their individual components. It is a device for separating oil and water mixtures into their distinct components. There are several types of oil-water separators. It is widely used in industrial and environmental settings to treat wastewater and stormwater runoff. Each has a unique oil separation capability and is employed in a variety of industries. The principal function of an oil-water separator is to separate oil and other hydrocarbons from water before it is released into the environment.

Oil water separators are designed and chosen based on oil separation performance specifications and life cycle cost factors. The term “oil” can refer to mineral, vegetable, and animal oils, as well as a variety of hydrocarbons.

Here’s a basic overview of how oil-water separators work:

- Inlet Zone: When polluted water enters the separator, it normally travels through an intake zone with a lower flow velocity. This causes larger oil droplets to rise to the surface due to buoyancy.

- Separation Chamber: The primary separation chamber is intended to give a prolonged detention time for the water, allowing the oil to ascend and create a layer on the surface. Baffles or coalescing plates can improve separation by trapping and accumulating oil.

- Oil Skimming: An oil skimmer or other mechanism is used to remove the floating oil from the surface of the water. This can be a mechanical skimmer, a floating weir, or other similar devices.

- Outlet Zone: After the separation process, the cleaned water is allowed to exit the separator, typically from a lower portion of the tank. The treated water should meet regulatory standards for oil content before being discharged.

There are various types of oil-water separators, including:

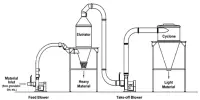

- Gravity Separators: These rely on the difference in density between oil and water, allowing the oil to float to the surface.

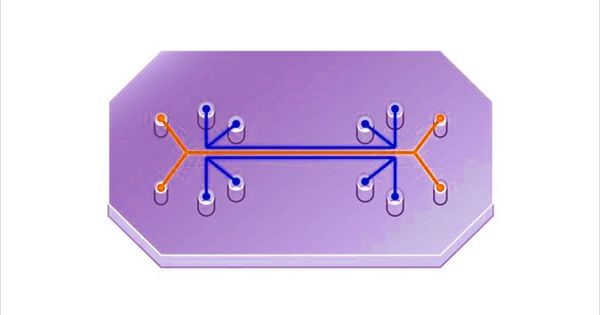

- Coalescing Plate Separators: These separators use coalescing plates to enhance the separation of oil droplets from water.

- API Separators: Commonly used in the petroleum industry, American Petroleum Institute (API) separators use gravity and the difference in specific gravities of oil and water to achieve separation.

- Hydrocyclone Separators: These use centrifugal force to separate oil and water.

Oil-water separators are critical for environmental protection because they prevent oil contamination in water bodies and ensure that environmental rules are followed. They are employed in many industries, including manufacturing, automotive, petrochemical, and food processing, where oily effluent is produced. Oil-water separators require proper maintenance and monitoring to perform efficiently over time.