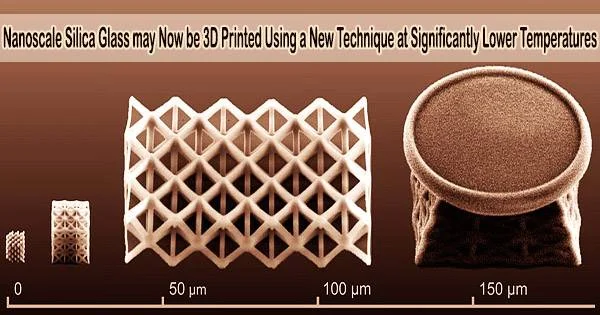

Researchers from the University of California, Irvine, Edwards Lifesciences, and Karlsruhe Institute of Technology have created a method to 3D print nanoscale glass structures at substantially lower temperatures than previous techniques.

Jens Bauer, Cameron Crook, and Tommaso Baldacchini used their method to print a range of nanostructures in their study, which was published in the journal Science. In the same journal issue, Paolo Colombo and Giorgia Franchin from the University of Padova published a Perspective article explaining the processes utilized to print nanoscale glasses and ceramics as well as the work done by the team on this new endeavor.

In recent years, 3D printing has been applied to a variety of applications, resulting in impressive works of art, less expensive products and highly detailed physical models. One application that has generated interest is 3D printing objects at the nanoscale such objects are of use in creating tiny electronic devices, particularly those parts that use light.

Up until now, most such applications have been limited to producing objects made from polymers due to the ease with which the base material can be melted and then allowed to harden by cooling.

But polymers do not provide the resolution needed for light-based nano-photonics. Unfortunately, due to the extraordinarily high temperatures necessary for sintering (melting to form a solid mass), attempts to print 3D glass structures have only partially succeeded. The study team developed a new method for printing nanoscale structures at temperatures that are almost half those of conventional techniques.

The researchers encased polyhedral oligomeric silsesquioxane molecules in a liquid resin cage-like structure rather than employing suspended silica nanoparticles as in prior techniques.

The team then used the resin as an ink to 3D print objects and then heated them to 650°C (other methods requiring heating to 1100°C). The biological components were destroyed by heating, which also transformed the cages into a continuous glass substance.

The team suggested using their method for on-chip printing of optical-grade fused silica after testing it by 3D printing microlenses and other microscopic items.